Magnumite

Ultimate Member

Poking the fire a little bit.

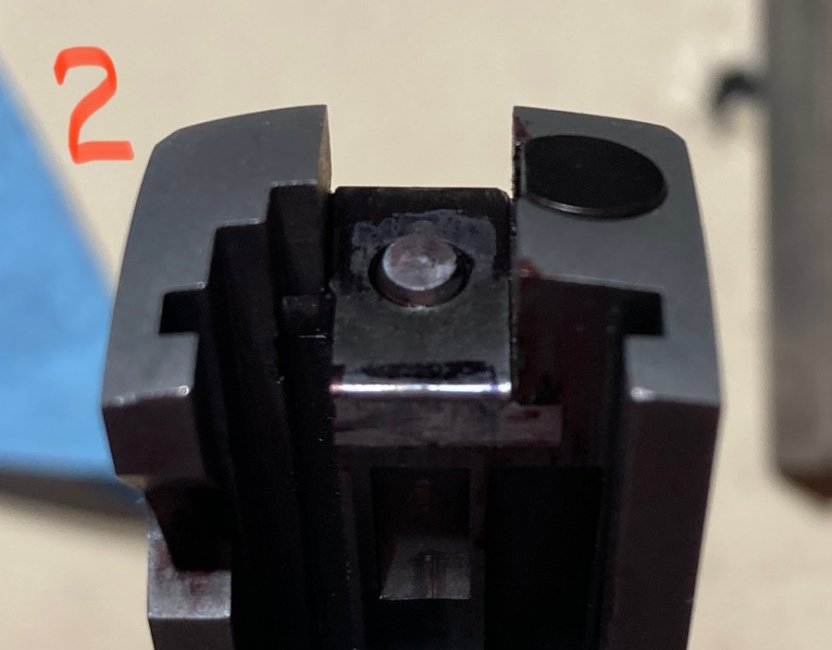

Fitted an EGW flat bottom firing pin stop precut for BoMar rear sights. All upper corners and edges were beveled and smoothed to facilitate install with tighter fitting. All vertical corners relieved and smoothed.

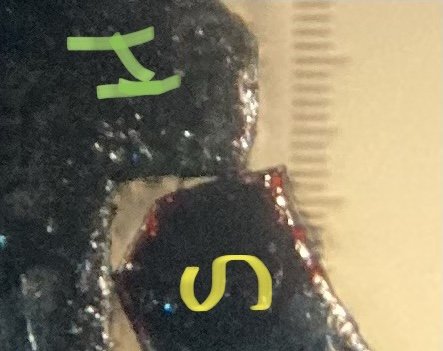

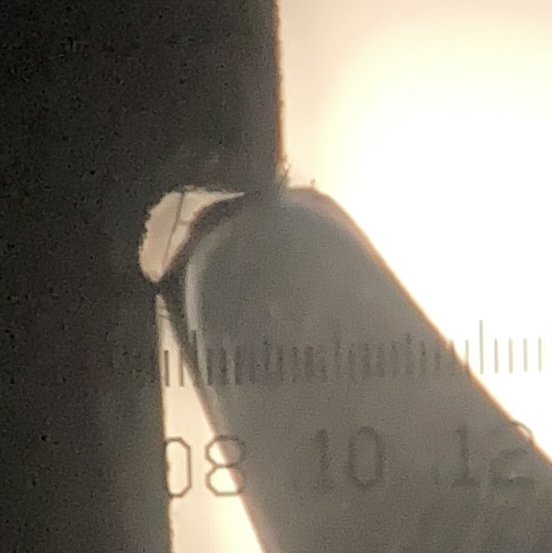

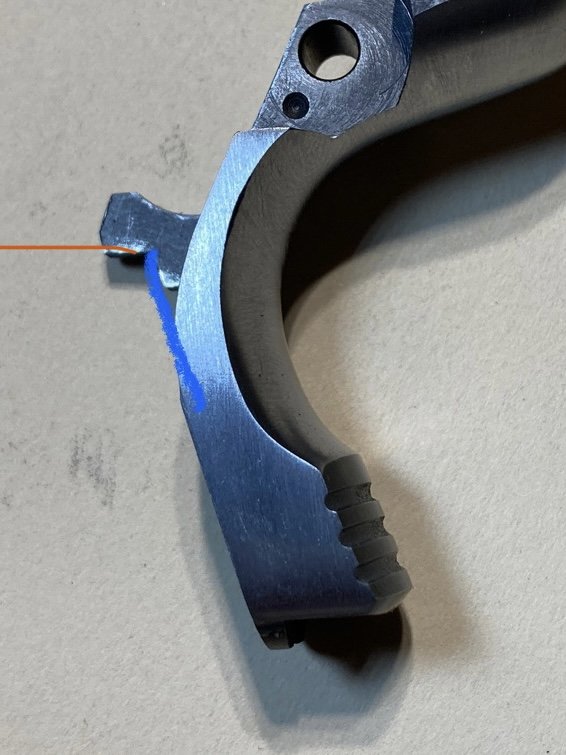

Extractor tip tuned, before and after pics.

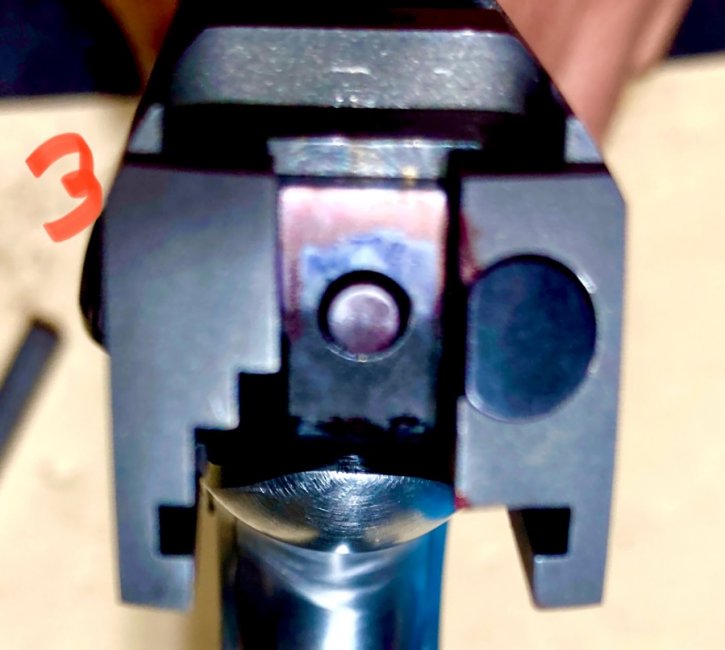

Adjust extractor tension. With tension applied to the extractor I rap the back of the adjuster to set the tension. This is akin to hitting the vise when laterally tightening the slide rails

Fitted an EGW flat bottom firing pin stop precut for BoMar rear sights. All upper corners and edges were beveled and smoothed to facilitate install with tighter fitting. All vertical corners relieved and smoothed.

Extractor tip tuned, before and after pics.

Adjust extractor tension. With tension applied to the extractor I rap the back of the adjuster to set the tension. This is akin to hitting the vise when laterally tightening the slide rails

Attachments

-

48995394-2DFA-4940-92B0-BF4D44D4CAA4.jpeg95.2 KB · Views: 127

48995394-2DFA-4940-92B0-BF4D44D4CAA4.jpeg95.2 KB · Views: 127 -

80D06146-921B-41EB-87CB-10614016C20D.jpeg77.7 KB · Views: 129

80D06146-921B-41EB-87CB-10614016C20D.jpeg77.7 KB · Views: 129 -

EC1919AA-B6F7-42E9-9DDC-29AE9F70AF3A.jpeg14.2 KB · Views: 124

EC1919AA-B6F7-42E9-9DDC-29AE9F70AF3A.jpeg14.2 KB · Views: 124 -

D3757D40-050B-412F-A663-A3E9D2F4D4B3.jpeg13.9 KB · Views: 122

D3757D40-050B-412F-A663-A3E9D2F4D4B3.jpeg13.9 KB · Views: 122 -

BBBA145E-4CAA-4A84-9C3A-ECD895FBB7F9.jpeg90.2 KB · Views: 125

BBBA145E-4CAA-4A84-9C3A-ECD895FBB7F9.jpeg90.2 KB · Views: 125 -

56678D47-7E6C-4664-B8E7-4C69A3841181.jpeg62 KB · Views: 125

56678D47-7E6C-4664-B8E7-4C69A3841181.jpeg62 KB · Views: 125