I'm beginning to realize that my interest in building machines is going to compliment my new found interest in shooting.

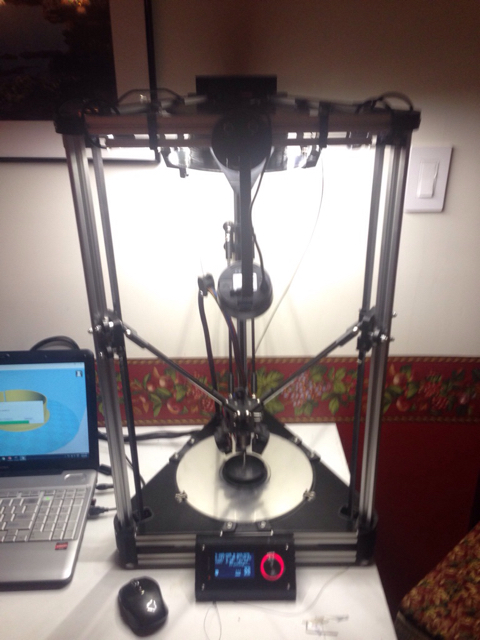

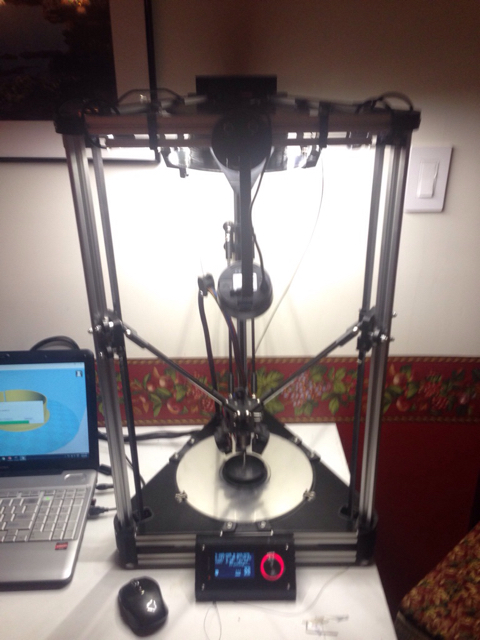

I built this 3D printer about 6 months ago.

https://vimeo.com/175477757

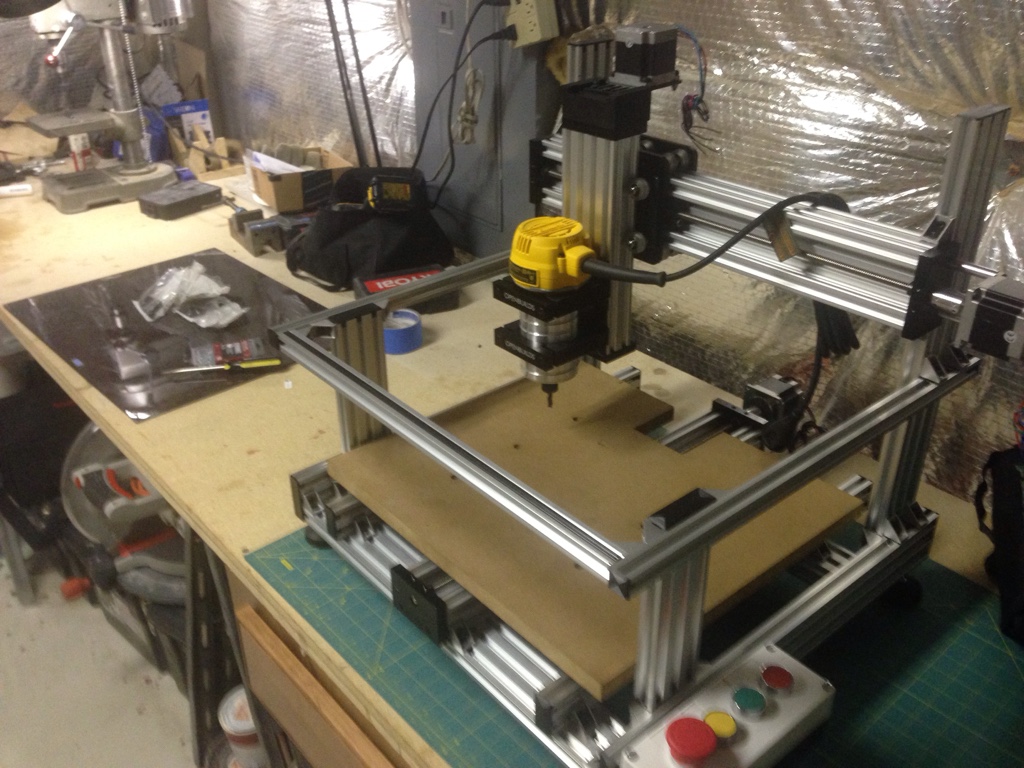

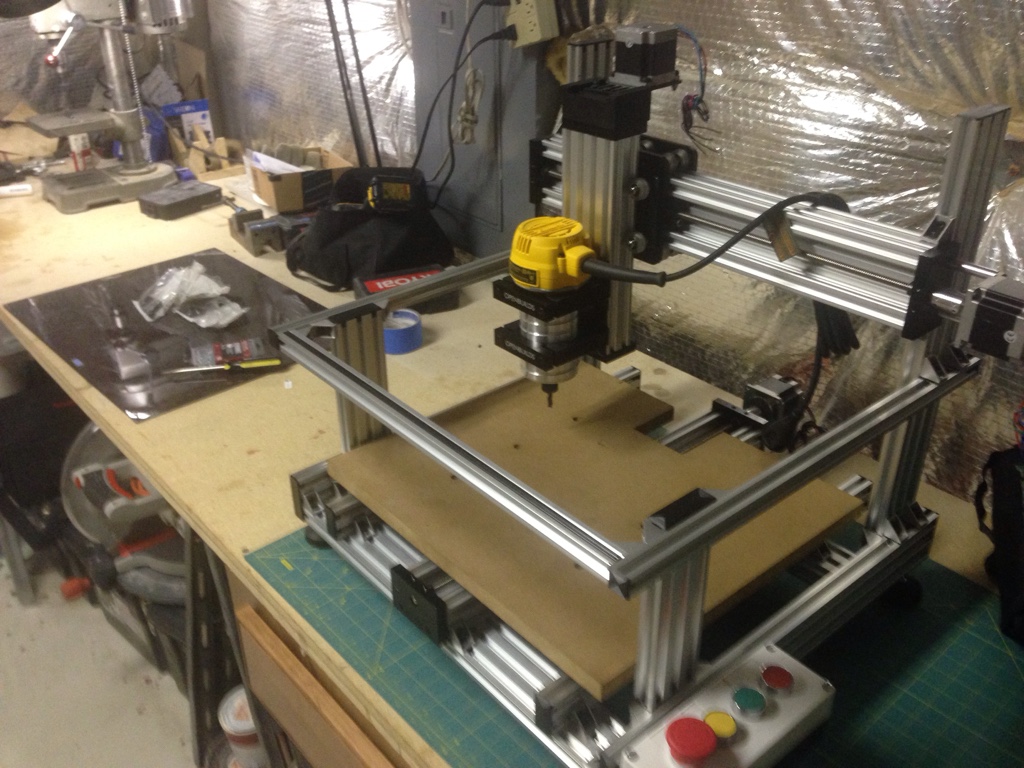

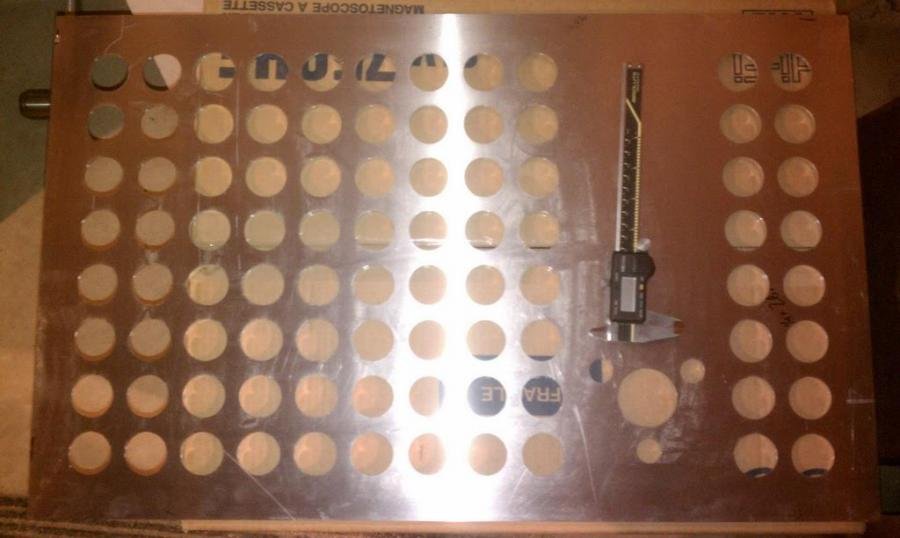

I had intended to use that to build parts for a DLP printer. However after some research it seemed that my DLP design would be best achieved by having the ability to make aluminum and plexiglas gusset plates. So I switched gears and decided to build a tabletop cnc router.

Now I'm realizing that if I make the Router a but larger I could use it to finish 80% lowers and now I'm working towards that goal.

I've got a few in order, but I plan to make s few test blocks in MDF first to make sure I program the G-code correctly before screwing up metal.

I figure the worst case scenario is that I find some limitation in the machine design or my ability to create the CNC program I could easily create my own 80% lower jig set. They were selling them for $150 at the show last week and thats about 1/4 the cost of the parts for the CNC.

DLP printer project is on hold for now.

I'll post a followup if Im successful.

Sent from my iPhone using Tapatalk

I built this 3D printer about 6 months ago.

https://vimeo.com/175477757

I had intended to use that to build parts for a DLP printer. However after some research it seemed that my DLP design would be best achieved by having the ability to make aluminum and plexiglas gusset plates. So I switched gears and decided to build a tabletop cnc router.

Now I'm realizing that if I make the Router a but larger I could use it to finish 80% lowers and now I'm working towards that goal.

I've got a few in order, but I plan to make s few test blocks in MDF first to make sure I program the G-code correctly before screwing up metal.

I figure the worst case scenario is that I find some limitation in the machine design or my ability to create the CNC program I could easily create my own 80% lower jig set. They were selling them for $150 at the show last week and thats about 1/4 the cost of the parts for the CNC.

DLP printer project is on hold for now.

I'll post a followup if Im successful.

Sent from my iPhone using Tapatalk

Excellent choice if using Mach.

Excellent choice if using Mach.