Speedluvn

Active Member

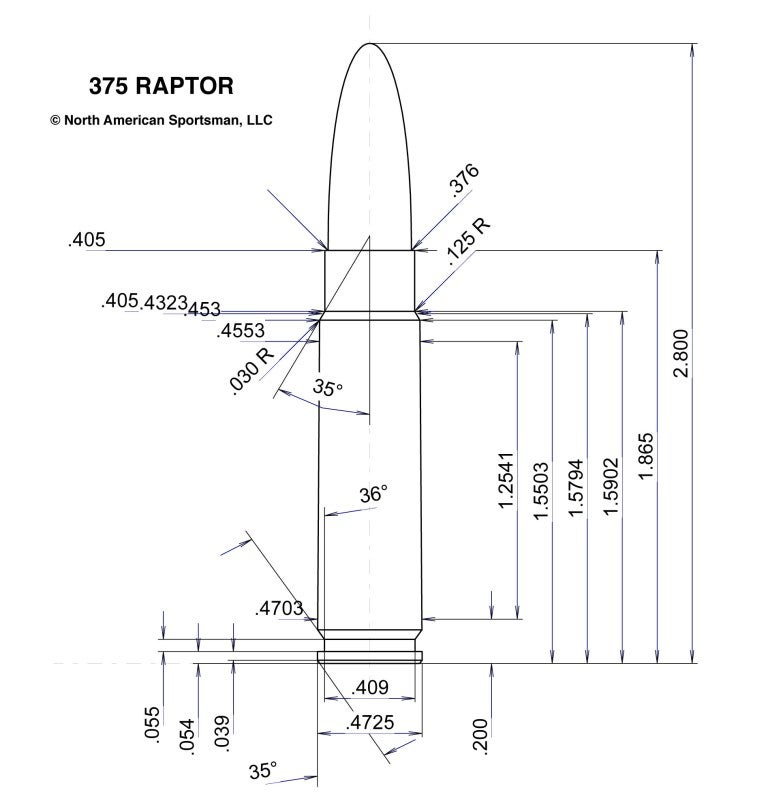

I’ve been reloading for about 4 years or so. I reload every caliber that I shoot. I rarely buy loaded ammo. With that said, I just completed a 375 Raptor build on an AR10 platform.

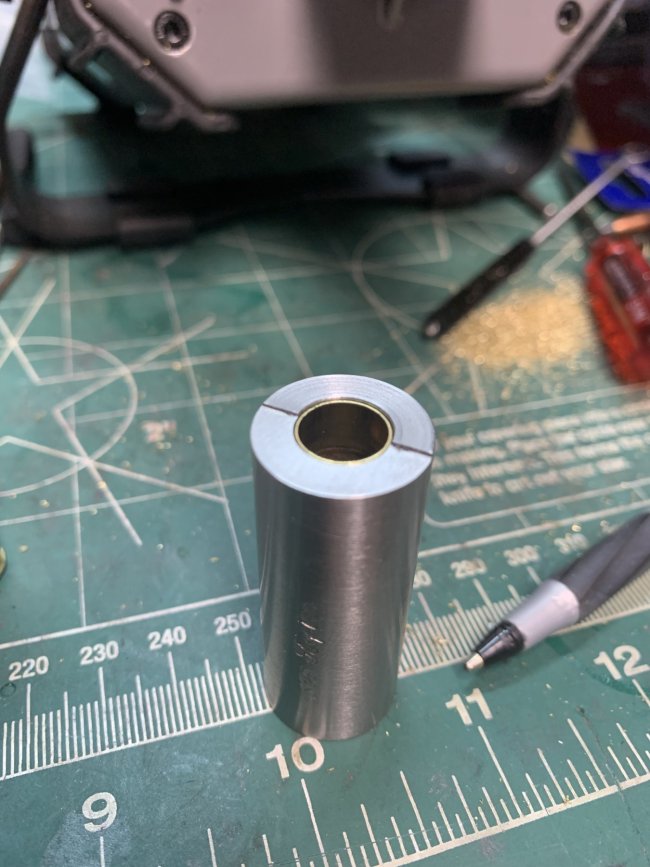

I loaded about 20 rounds and shot them this weekend. I experienced some blown primers and other high pressure signs. I came home and checked my data. I purchased a case length guage from an eBay seller.

My question is the cartridge case in the guage should be flesh, correct? I’m seeking another set of eyes on this issue.

I loaded about 20 rounds and shot them this weekend. I experienced some blown primers and other high pressure signs. I came home and checked my data. I purchased a case length guage from an eBay seller.

My question is the cartridge case in the guage should be flesh, correct? I’m seeking another set of eyes on this issue.