Archeryrob

Undecided on a great many things

Powder coating bullets for 6.8 SPC today and tried to use the blue I had moisture trouble with. It had two desiccant packs in it and couldn’t get the powder to stick on spoty on half of each bullet. The powder was either bad it won’t recover from moisture that affected it.

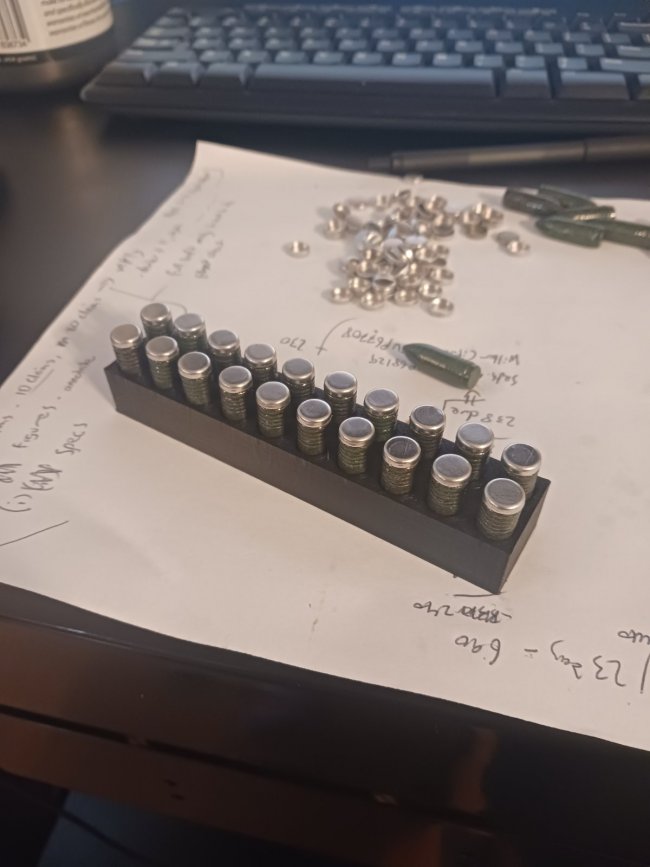

Washed and dried and Eastwood green and the last of 609 is backing now. Someone on here spoke about using these Amazon mini ice cube trays. These things are awesome

Washed and dried and Eastwood green and the last of 609 is backing now. Someone on here spoke about using these Amazon mini ice cube trays. These things are awesome

It literally tranfered powder paint to the anvil I hit it so hard

It literally tranfered powder paint to the anvil I hit it so hard