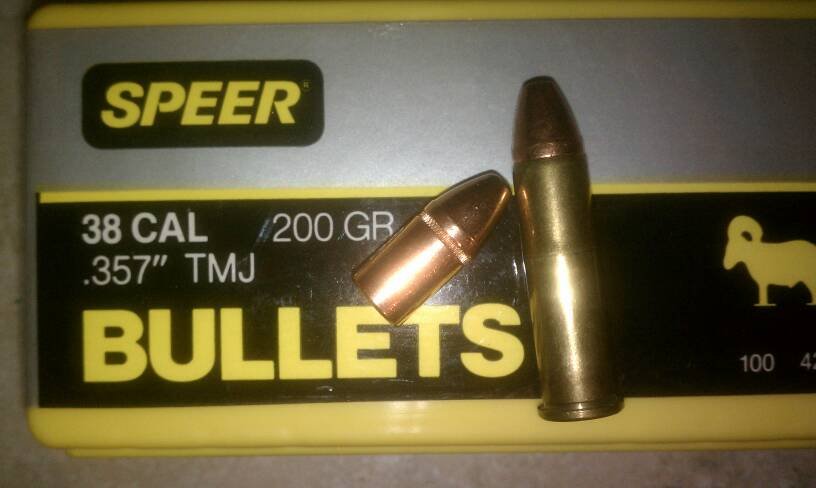

Digging through a bunch of old stuff I found about 100 .357 loads I did in college (20 yrs ago). They are 200gr silhouette target loads. They developed a tiny bulge at the bottom edge of the bullet. Some of my other loads did this but these are about 0.002" too large diameter to chamber in the GP100. That was a first. Any easy fix or just toss them? I found the remaining half box of Speer bullets too.

First time posting pics from my phone w tapatalk, hope it works...

First time posting pics from my phone w tapatalk, hope it works...