The one justiw has pictured is cocobolo. I have two of his, both with black palm scales, and bought one for my father. One of mine (and my father's) are the same blade profile as pictured in the same AEB-L steel. Anyone wanting a razorblade for the kitchen, these are it.

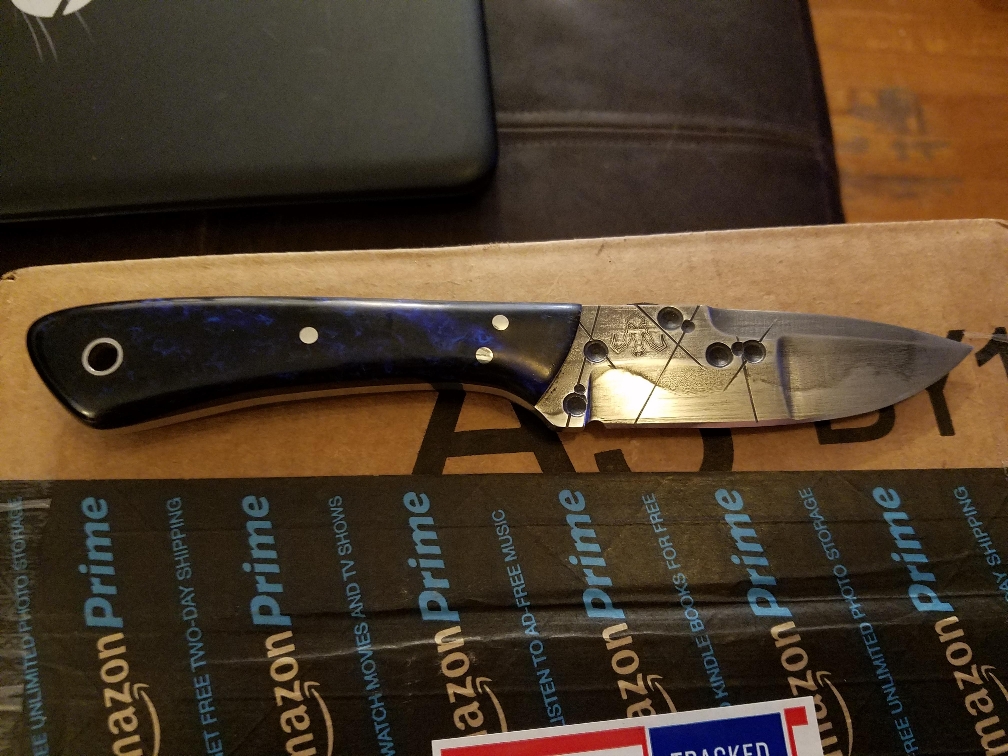

This is a custom blade he did for me. It's a middle ground between carving and boning knife and so far has been excellent. It's a good one-knife for dinner making but I'm looking forward to putting it to use processing deer.That's beautiful! Very nice job. What wood did you use for the handle scales?

JoeR