Yingpin

Ultimate Member

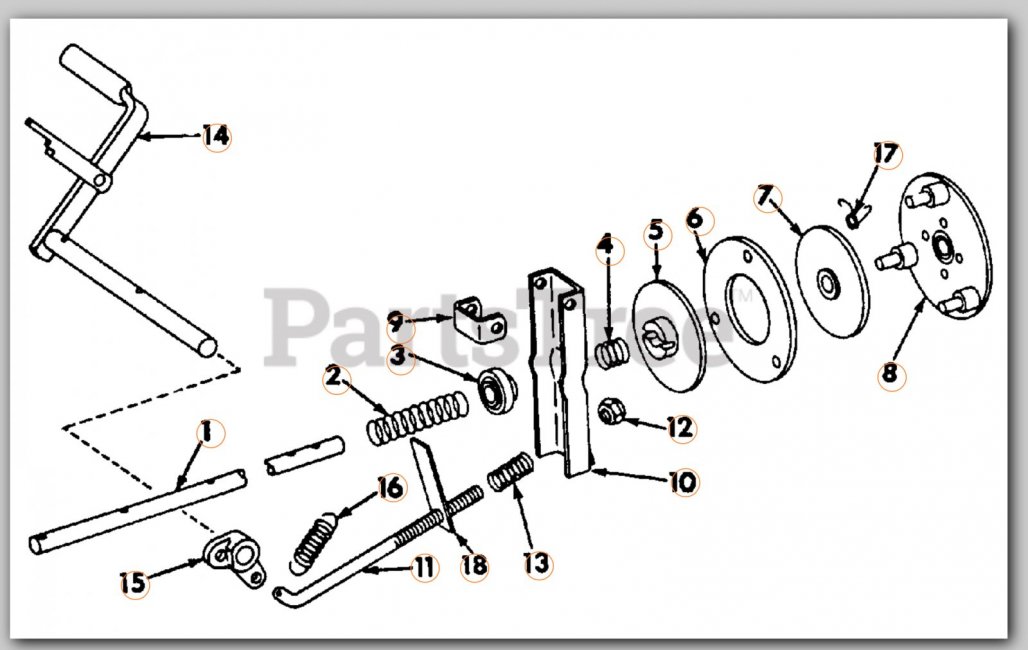

Last year the throwout bearing in my cub cadet 124 crumbled and I was not able to shift the garden tractor. I ordered the new bearing and began taking it apart to get the motor moved in order to access the driveshaft and although it is tight, the roll pins are accessible. This is were the project stopped for many months. I was not able to get the pins out with a punch and hammer so there it sits and has sat since last fall.

I wanted to see if there is anyone here that has experience with this project and would be willing to assist. I would love to learn what I am doing wrong and also know that it is being done right. I live in Kingsville, right off of Mt. Vista Road by Hubers Farm and would be happy to pay someone who can assist.

I wanted to see if there is anyone here that has experience with this project and would be willing to assist. I would love to learn what I am doing wrong and also know that it is being done right. I live in Kingsville, right off of Mt. Vista Road by Hubers Farm and would be happy to pay someone who can assist.