Doco Overboard

Ultimate Member

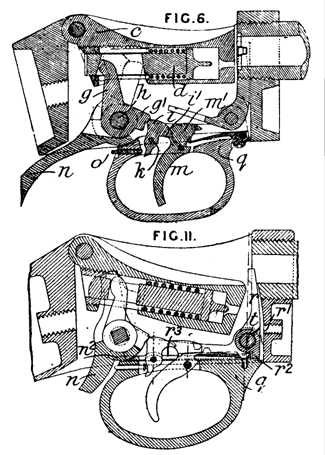

I'm going to build up a rifle that looks like, or is a close facsimile of this one.

View attachment 337019

Need to scrounge up parts from a SMLE- uncut barrel. Front timber,rear sights stock bits etc.

If you have any Martini spares or stock woods Ill be looking for those parts as well to have a selection to choose from/dress out.

Hopefully it'll turn out into a decent shooter/curiosity piece once completed.

View attachment 337019

Need to scrounge up parts from a SMLE- uncut barrel. Front timber,rear sights stock bits etc.

If you have any Martini spares or stock woods Ill be looking for those parts as well to have a selection to choose from/dress out.

Hopefully it'll turn out into a decent shooter/curiosity piece once completed.