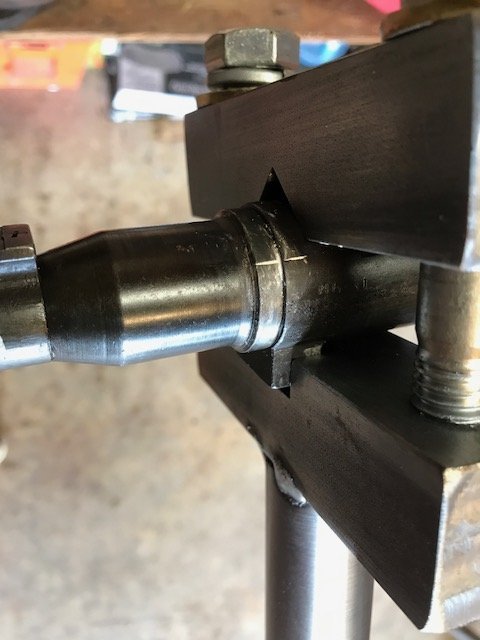

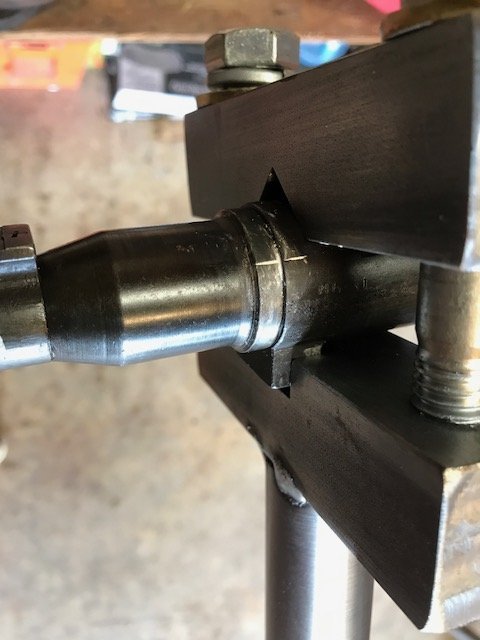

Home made action wrench. Made by parting a trash barrel on a 99 action at the stub, capturing the receiver in the barrel vise and then turning the barrel off with a chain wrench and then using the stripped action for a pattern. It mimics a Wilcox Mauser/Springfield wrench with just a milled out slot for the lug. When I have time Ill have milled the other side of the bottom to fit the Enfield No 4 which has a lug that is not square until the bottom but has a radius originating from the receiver tube that tapers towards the lugs bottom which is then finished square. The Enfield lug is also not as wide. The handle is also five inches longer and is knurled for a good grip. Where the bolts pass through the body the holes are oblong which helps center the receiver until the bolts are fully tightened. The idea here is that because there is no inner ring to support to receiver on the inside or a projection on the exterior like the US rifles, it will help prevent oval-ling the receiver on crusty Jap or N04 actions that are hard to separate which have no flat on the bottom for preventing the wrench to slip or apply torque unevenly while under pressure. The previous owner re chambered the barrel to 30'06 and ruined it because the o6 is smaller than 7.7 at the base of the cartridge which = bulge, disqualifying the barrel. There is a milled flat on the 99 action directly behind the lug which somehow must have been used during original assembly.

Home made action wrench. Made by parting a trash barrel on a 99 action at the stub, capturing the receiver in the barrel vise and then turning the barrel off with a chain wrench and then using the stripped action for a pattern. It mimics a Wilcox Mauser/Springfield wrench with just a milled out slot for the lug. When I have time Ill have milled the other side of the bottom to fit the Enfield No 4 which has a lug that is not square until the bottom but has a radius originating from the receiver tube that tapers towards the lugs bottom which is then finished square. The Enfield lug is also not as wide. The handle is also five inches longer and is knurled for a good grip. Where the bolts pass through the body the holes are oblong which helps center the receiver until the bolts are fully tightened. The idea here is that because there is no inner ring to support to receiver on the inside or a projection on the exterior like the US rifles, it will help prevent oval-ling the receiver on crusty Jap or N04 actions that are hard to separate which have no flat on the bottom for preventing the wrench to slip or apply torque unevenly while under pressure. The previous owner re chambered the barrel to 30'06 and ruined it because the o6 is smaller than 7.7 at the base of the cartridge which = bulge, disqualifying the barrel. There is a milled flat on the 99 action directly behind the lug which somehow must have been used during original assembly.You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ARISAKA ACTION WRENCH

- Thread starter Doco Overboard

- Start date

The #1 community for Gun Owners of the Northeast

Member Benefits:

No ad networks! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Re Assembling the Arisaka

So I scored a real nice 7.7 barrel for $30 with shipping and put everything back. I was going to put all this stuff together on a real nice sporter stock but decided I couldn't do it so I scrubbed a bunch of parts, patched the stock up and decided not to. Between the three barrels I had in front of me one being the new one, index was all over the place but luckily the replacement barrel and un-ground receiver were only about 9/32 apart. Plus I have enough parts left over for another barrelled receiver. Once the new barrel checked out for nothing spooky I measured for head-space which is a real pain on the Arisaka and figured it right around .010 without crush using my HS gauge which can be seen next to a 3006 cartridge for comparison in one of the pictures. Test firing the one cartridge I had left indicated .008 stretch and no abnormalities for being out of round near the head of the case so it will make a good shooter rifle. The Hornady ammo measured .471 at the head The rifle itself is interesting because when it was stripped the barrel channel and stock was lined with a heavy grease and the stock was beat to pieces from being thrown into a pile of rifles and covered in decades of dirt and sand grit. Alot of rust and frozen band/tang screws. Lord only knows what sort of cave it came out of but it came along way to get to me.

So I scored a real nice 7.7 barrel for $30 with shipping and put everything back. I was going to put all this stuff together on a real nice sporter stock but decided I couldn't do it so I scrubbed a bunch of parts, patched the stock up and decided not to. Between the three barrels I had in front of me one being the new one, index was all over the place but luckily the replacement barrel and un-ground receiver were only about 9/32 apart. Plus I have enough parts left over for another barrelled receiver. Once the new barrel checked out for nothing spooky I measured for head-space which is a real pain on the Arisaka and figured it right around .010 without crush using my HS gauge which can be seen next to a 3006 cartridge for comparison in one of the pictures. Test firing the one cartridge I had left indicated .008 stretch and no abnormalities for being out of round near the head of the case so it will make a good shooter rifle. The Hornady ammo measured .471 at the head The rifle itself is interesting because when it was stripped the barrel channel and stock was lined with a heavy grease and the stock was beat to pieces from being thrown into a pile of rifles and covered in decades of dirt and sand grit. Alot of rust and frozen band/tang screws. Lord only knows what sort of cave it came out of but it came along way to get to me.

Thanks, the Jap rifles are curious and must be getting popular because parts are through the roof. I still need to get a lower band for it which are going for more than blued 03 band. I see some nice stocks for sale and they and rifle parts are high compared to what they were years ago. I sold all my jap stuff years ago and had some odds and ends around that I wanted to do something with. You can pay more for a safety knob and some bottom metal than a barreled action or even a sported rifle than you can shoot. And then find a pristine barrel for twenty some dollars and shipping. Funny how so much thought went into creating such a strong action and bolt mechanism with gas handling and engineered safety capability and then relegate troops to human waves and banzai attacks in a few short years when things went bad for them. Curious people and weapons. I went through an all matching and un-ground type 2 paratroop rifle for a guy that was built like a tank. The two halves were stout as a dam engine block and weighed a ton for a jump rifle. He traded his brother for a pocket 38 back in the day and all it needed was some light rust rubbed out with a piece of copper. He dropped it off at a Gunsmith who held it for like six or more months who told him that he was having a hard time checking the chamber and that it might be dangerous to fire. Waiting for him to not return or drop the bayonet off I guess. We found a sling, shot it 9 times cleaned and greased it up I gave him an original muzzle cover to make it complete and I kept one round which is what I test fired this one with. My kid video taped the test fire because he thought it was going to blow up for you tube or something.

I just used a Wilcox for a pattern and my son knocked it out for me in his machine shop. The handle is a little longer than most and is very nicely knurled. I need to get him to mill out the recess for it to fit the #No.4. which is what I'm going to do next. Another easy to make wrench for a flat bottomed receiver is just a semi circular piece of steel made from a piece of pipe with a handle welded to the top and a square opening cut through it that accepts a wedge shaped flat steel bar. The tighter you drive the wedge in the more purchase you get. Its also nice because with a few raps of a heavy mallet and your wrench is on and off without tightening bolts. The drawback to this one is that its hard to work up close to the barrel vise when viewing the witness marks on the Arisaka. Breaking the action loose is where the heft comes in. The Brownells system is nice for all the different applications it can be applied to. I bet it only took about 50-65lbs of torque to put this one together but sometimes theyre a bear to break loose. Especially the m17's which will tax lesser equipment.

Nice to have a son with a milling machine!

I always soak a few days with Kroil before I remove an old milsurp barrel. I haven't done a 1917 yet, but all my Mausers have come apart by either a good whack or hanging a weight on the end of the handle overnight. A piece of pipe makes a good breaker bar.

I always soak a few days with Kroil before I remove an old milsurp barrel. I haven't done a 1917 yet, but all my Mausers have come apart by either a good whack or hanging a weight on the end of the handle overnight. A piece of pipe makes a good breaker bar.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Forum statistics

Latest threads

-

-

-

-

-

Looking for used guns, optics, and parts, give us a call!

- Started by SandSGunsSOMD

- Replies: 0

-

Looking for used guns, optics, and parts, give us a call!

- Started by SandSGunsSOMD

- Replies: 0

-