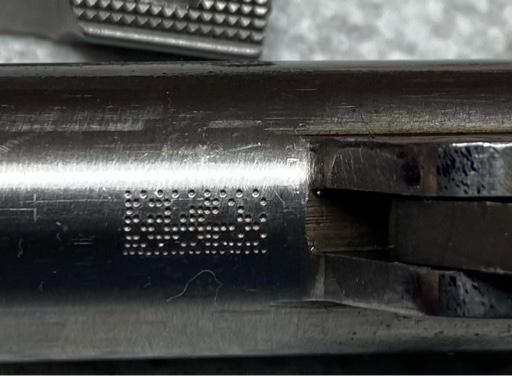

Here is the result

How does this come into play for a failure that occurs long before that link cams over to move the barrel up into the grooves to lock up?

Sent from my iPhone using Tapatalk

Because it's slowing down the timing sequence. The slide stop is "bumping" on that hump which causes a little bit of a stall, enough to slow down the timing needed to feed the next round.

There is a good possibility that there are other contributing factors as well. The feed ramp in the frame itself may not be deep enough which causes the round to stall a little coming out of the magazine, then the slide stop bumps, which causes another stall. It looks like the bevel on the link is chewed up a little bit, which could be a burr somewhere in the channel between the barrel legs and that can cause a little drag.

I saw you had checked extractor tension so I won't mention that. But, that is also a big contributor in failures to feed.

All of these things add up and eventually cause issues with feeding.