Hey, so I got my polymer 80 G17 to the range for the first time today. Pretty standard stuff for the build kit and Swenson non-threaded barrel and slide. Glock recoil spring assembly.

I ran most of a box of Remington 115gr UMC through it. Every other round was a light primer strike and it would successfully fire the round if I reloaded it. Also the slide was locking back on empty mags only about 20% of the time. Some miscellaneous handloads of JHP ran slightly better. Of 20 rounds I had 4 rounds (so happened twice) where I had two rounds fire successfully in a row before a light primer strike.

I loaded 15 rounds of Winchester 147gr JHP, definitely much stouter loads (white box) based on recoil. I had 1 light primer strike and it locked back successfully all 4 times (I loaded 2 rounds, fired them both. I loaded 3 rounds, fired them both. Then I loaded 10, 5 fired fine, light primer strike, next 4 fine, reloaded and fired the light strike again).

My best guess is something is causing some undue resistance on the slide. Maybe strong recoil spring and needs to be locked back for a few days to help out?

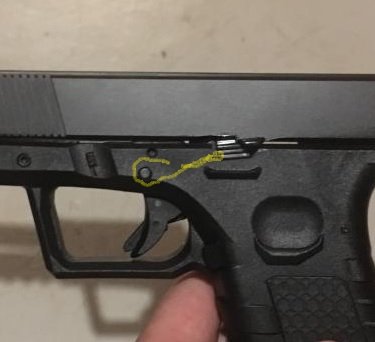

I noticed that the slide wouldn't lock in to battery properly all the time and the slide would need a tap to go in to battery. Not sure if that points more towards a slide/barrel fitment issue or if the wear point is somewhere else.

Maybe the thing just needs a few hundred rounds to break it in. I did just order 400rnds of mixed 124 and 147gr stouter loads (Mostly +P or NATO). See how well it runs with that and probably to help break it in better.

Thoughts? Nothing seems to be binding and it runs by hand just fine. Sling shoting it or releasing the slide with the slide release and it goes in to battery I think every time with a live round. There may have been one or two where I had to tap it. Since by the end I was loading each of my magazines (all 5) with a single round each.

Every single time it went bang properly when I ran the slide manually. So I think this is again pointing towards an issue with the slide not running all the way back either from resistance of the spring is too strong and it needs some break in.

Any help would be appreciated. I am going to attack the wear surfaces with some polishing compound for a bit and re-lube it. For the areas I milled the plastic (it is a V1.5) I am going to hit with some 400 grit as I only finished it with 220.

I ran most of a box of Remington 115gr UMC through it. Every other round was a light primer strike and it would successfully fire the round if I reloaded it. Also the slide was locking back on empty mags only about 20% of the time. Some miscellaneous handloads of JHP ran slightly better. Of 20 rounds I had 4 rounds (so happened twice) where I had two rounds fire successfully in a row before a light primer strike.

I loaded 15 rounds of Winchester 147gr JHP, definitely much stouter loads (white box) based on recoil. I had 1 light primer strike and it locked back successfully all 4 times (I loaded 2 rounds, fired them both. I loaded 3 rounds, fired them both. Then I loaded 10, 5 fired fine, light primer strike, next 4 fine, reloaded and fired the light strike again).

My best guess is something is causing some undue resistance on the slide. Maybe strong recoil spring and needs to be locked back for a few days to help out?

I noticed that the slide wouldn't lock in to battery properly all the time and the slide would need a tap to go in to battery. Not sure if that points more towards a slide/barrel fitment issue or if the wear point is somewhere else.

Maybe the thing just needs a few hundred rounds to break it in. I did just order 400rnds of mixed 124 and 147gr stouter loads (Mostly +P or NATO). See how well it runs with that and probably to help break it in better.

Thoughts? Nothing seems to be binding and it runs by hand just fine. Sling shoting it or releasing the slide with the slide release and it goes in to battery I think every time with a live round. There may have been one or two where I had to tap it. Since by the end I was loading each of my magazines (all 5) with a single round each.

Every single time it went bang properly when I ran the slide manually. So I think this is again pointing towards an issue with the slide not running all the way back either from resistance of the spring is too strong and it needs some break in.

Any help would be appreciated. I am going to attack the wear surfaces with some polishing compound for a bit and re-lube it. For the areas I milled the plastic (it is a V1.5) I am going to hit with some 400 grit as I only finished it with 220.