You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Deal on Polymer80 compact.

- Thread starter teratos

- Start date

The #1 community for Gun Owners of the Northeast

Member Benefits:

No ad networks! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Fox123

Ultimate Member

In the 17 that spring is long (in the vertical) and pokes pretty far down in a grove/slot going down into the vertical portion of the trigger guard.

On this 19 it seems like it only sits in there loosely and kinda wedged itself when under tension. Is that correct or should it push down into a slot?

On this 19 it seems like it only sits in there loosely and kinda wedged itself when under tension. Is that correct or should it push down into a slot?

Fox123

Ultimate Member

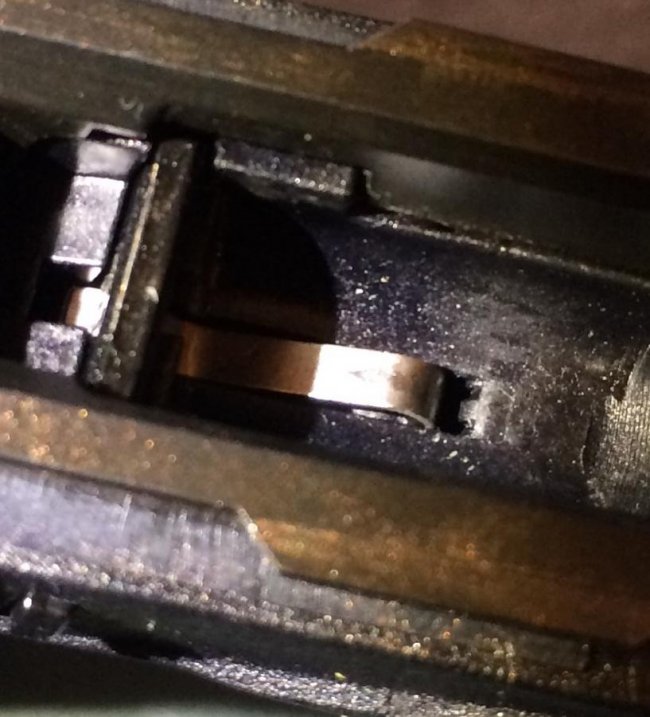

Also looks like it bulges/bows up into the recoil spring channel just a little and can see light rub marks on the top of it from the recoil spring

BUFF7MM

☠Buff➐㎣☠

The slide lock spring is different on the Glock 17 vs 19 vs 26. Your spring should be the one for a compact (19).

Fig 80 in the 2009 Glock Armorers' manual shows the differences.

Ok so I was reading your post and I thought that I might have got the wrong kit but I checked my order history from Midway and I had purchased the G19 kit

https://www.midwayusa.com/product/954622/glock-frame-parts-kit-glock-19-9mm-luger

Well it seem that the spring was my culprit, maybe it was put in the kit by mistake

. I really didn't have anything to compare it to so I stripped the gun again and removed the slide stop and the spring, replaced the slide and it moved just like a factory Glock should. I snipped a small portion of the spring from the end that fits into the frame and it wasn't protruding into the spring channel anymore. Reassembled the build and now the slide moves effortlessly.

. I really didn't have anything to compare it to so I stripped the gun again and removed the slide stop and the spring, replaced the slide and it moved just like a factory Glock should. I snipped a small portion of the spring from the end that fits into the frame and it wasn't protruding into the spring channel anymore. Reassembled the build and now the slide moves effortlessly.Picture of how much spring I cut:

Attachments

...

Well it seem that the spring was my culprit, maybe it was put in the kit by mistake. I really didn't have anything to compare it to so I stripped the gun again and removed the slide stop and the spring, replaced the slide and it moved just like a factory Glock should. I snipped a small portion of the spring from the end that fits into the frame and it wasn't protruding into the spring channel anymore. Reassembled the build and now the slide moves effortlessly.

Picture of how much spring I cut:

Glad you got it worked out. I have the same bend on my spring. The slide stop spring channel on mine was filled with plastic debris from filing. A few shakes, smacks and scrapes were needed to clean the plastic out of the channel. Then I inserted the spring and slide lock.

Edit: No need to mod the spring. A 3/32 punch will fully seat the original one.

Last edited:

That is correct, it just kinda fits down into the cutout, doesn't really insert tightly, but when you put the slide stop in, it will stay in place.In the 17 that spring is long (in the vertical) and pokes pretty far down in a grove/slot going down into the vertical portion of the trigger guard.

On this 19 it seems like it only sits in there loosely and kinda wedged itself when under tension. Is that correct or should it push down into a slot?

Ok so I was reading your post and I thought that I might have got the wrong kit but I checked my order history from Midway and I had purchased the G19 kit

https://www.midwayusa.com/product/954622/glock-frame-parts-kit-glock-19-9mm-luger

Well it seem that the spring was my culprit...

Picture of how much spring I cut:

Edited with original text below. Other folks report that a 3/32 punch and some force is all that is needed to fully seat the slide lock spring. (Ref. Replies below this one) Edit: I have replaced my modified spring with a factory new one using a 3/32 punch to fully seated it.

I was thinking about your post and how my spring also sits up a bit. I used the same parts kit from Midway. So I got out my Dremel, popped out the spring and ground off about 1.5 mm to the offset bend - just a bit less than you did. I put the spring back in and it now sits flat in the channel.

My gun was running fine without this mod, but I would recommend it to anyone that bought Midway's LPK.

I also swapped out the extended mag release Midway sent with their kit for a standard (G287) mag catch release.

Last edited:

Interesting... I'll pull out my 30 and compare it later. My spring does sit up just a bit where it bends coming up out of the receiver, but I don't think it's interfering, though I could be wrong, it does protrude into the action spring channel just a bit...I was thinking about your post and how my spring also sits up a bit. I used the same parts kit from Midway. So I got out my Dremel, popped out the spring and ground off about 1.5 mm to the offset bend - just a bit less than you did. I put the spring back in and it now sits flat in the channel.

My gun was running fine without this mod, but I would recommend it to anyone that bought Midway's LPK. I also swapped out the extended mag release Midway sent with their kit for a standard (G287) mag catch release.

Hmmm... you might be right.. after looking at my spring closely, I can see a little wear track down the center of it. It really doesn't interfere that you can feel, but I'll investigate further later on.. (yes, Midway P80 LPK)

sorry, sucky cell pic...

sorry, sucky cell pic...

Attachments

BUFF7MM

☠Buff➐㎣☠

I had used compressed air and a pick to clean out the slot before I had initially installed the spring so I was pretty sure it was cleaned out before the spring went in.I was thinking about your post and how my spring also sits up a bit. I used the same parts kit from Midway. So I got out my Dremel, popped out the spring and ground off about 1.5 mm to the offset bend - just a bit less than you did. I put the spring back in and it now sits flat in the channel.

My gun was running fine without this mod, but I would recommend it to anyone that bought Midway's LPK. I also swapped out the extended mag release Midway sent with their kit for a standard (G287) mag catch release.

Interesting... I'll pull out my 30 and compare it later. My spring does sit up just a bit where it bends coming up out of the receiver, but I don't think it's interfering, though I could be wrong, it does protrude into the action spring channel just a bit...

My spring was sitting up like it is in your picture before I snipped the small portion off of it, now it sits below the channel and seems to let the slide stop work better. Before when the slide would travel forward into battery the stop would move up and down, now it's doing what it was meant to do.Hmmm... you might be right.. after looking at my spring closely, I can see a little wear track down the center of it. It really doesn't interfere that you can feel, but I'll investigate further later on.. (yes, Midway P80 LPK)

sorry, sucky cell pic...

Fox123

Ultimate Member

I was experiencing the same thing with the stop moving when going back into battery (not incredibly smoothly) and could feel gritty almost, I think the grit feeling was the recoil spring riding the slide stop spring and each of the coils rubbing off the hump like in the photo above, the slide stop jumping as each coil slid off.

Ground the stop spring just until the short bend on the end, tried reinstalling, didn't have as much spring tension on the stop so bent it up a little more.

Now installed and no more gritty feeling, and no more moving of the stop when cycling.

Ground the stop spring just until the short bend on the end, tried reinstalling, didn't have as much spring tension on the stop so bent it up a little more.

Now installed and no more gritty feeling, and no more moving of the stop when cycling.

I had used compressed air and a pick to clean out the slot before I had initially installed the spring so I was pretty sure it was cleaned out before the spring went in.

My spring was sitting up like it is in your picture before I snipped the small portion off of it, now it sits below the channel and seems to let the slide stop work better. Before when the slide would travel forward into battery the stop would move up and down, now it's doing what it was meant to do.

I used a dental pick, too. The sppring from Midway is fine. Use a 3/32 punch and it will fully seat. My original thought on this was wrong (quoted below).

My Original Text: You definitely found a problem with the Midway LPK slide stop spring. (edit: other folks report a punch and some force will fully seat the spring)

Last edited:

Did a little research this morning... I have a G30, so I stripped out the spring and slide stop and compared it to the spring that came with the Midway kit. I even took the 30 spring and stuck it in the 19 slide... fit like a glove, but it is a shorter reach spring for the 30, so it won't function properly, but... it shows me where the difference was.

The spring that came with the LPK is marked 2317, which is the correct part number for the 19 spring, but it sure has a longer leg than the 30 spring where is fits down into the receiver, so... I measured both... the 30 spring was approx 0.200" from the bottom of that leg that fits into the frame, to the top of the horizontal section where it's bent. The 19 spring from Midway was about 0.260" long in that section, so I took the dremel and shortened it to close to 0.200", dropped it in and it fits like a champ now.

The two springs compared 19 and 30 and the after pic as compared to the one from yesterday with no spring mods..

The spring that came with the LPK is marked 2317, which is the correct part number for the 19 spring, but it sure has a longer leg than the 30 spring where is fits down into the receiver, so... I measured both... the 30 spring was approx 0.200" from the bottom of that leg that fits into the frame, to the top of the horizontal section where it's bent. The 19 spring from Midway was about 0.260" long in that section, so I took the dremel and shortened it to close to 0.200", dropped it in and it fits like a champ now.

The two springs compared 19 and 30 and the after pic as compared to the one from yesterday with no spring mods..

Attachments

One other possibility, and I didn't try this before I cut a little off the spring.... I was just talking with a buddy that has built a couple and he said he had issues and wound up taking a punch (like a 3/32" punch) and just jamming the spring down hard into the frame and it did, eventually seat all the way down, almost like the slot in the frame is a little tight and ya just need to force it a bit. His fit fine with the same LPK and no mods to the spring.

Next time I order some Glock parts, I'll order a factory spring 2317 and try that..

Next time I order some Glock parts, I'll order a factory spring 2317 and try that..

- Aug 17, 2011

- 26,177

One other possibility, and I didn't try this before I cut a little off the spring.... I was just talking with a buddy that has built a couple and he said he had issues and wound up taking a punch (like a 3/32" punch) and just jamming the spring down hard into the frame and it did, eventually seat all the way down, almost like the slot in the frame is a little tight and ya just need to force it a bit. His fit fine with the same LPK and no mods to the spring.

Next time I order some Glock parts, I'll order a factory spring 2317 and try that..

I've been doing that with all the ones I've done/assisted with - no one told me to, just been doing it cause I felt the spring wasn't fully seated in the channel.

Huh, for once I'm ahead of the curve...

...he said he had issues and wound up taking a punch (like a 3/32" punch) and just jamming the spring down hard into the frame and it did, eventually seat all the way down, almost like the slot in the frame is a little tight and ya just need to force it a bit. His fit fine with the same LPK and no mods to the spring...

Now I'm curious. I used needle nose pliers to set the spring originally. I used a punch after I ground off the metal below the bend and I was able to seat it completely against the frame.

Was using the punch really all I needed to concentrate the pressure to seat the spring? I can see I'm going to have to pickup another spring to try this out again. (The answer is YES. I replaced the modded spring with a standard one.)

Last edited:

swierczekml

Active Member

- Apr 19, 2011

- 112

Was using the punch really all I needed to concentrate the pressure to seat the spring?

I had a similar issue with spring seating and a punch (with a fair amount of pressure) was all I needed to seat it properly and avoid interference with the recoil spring. No cutting required.

Finally got around to ordering two of the glock 19 compacts, 2 just incase I screw up because this will be my first time doing something like this.

Just take your time and go slow, you'll be fine, and if you do have any problems just post it here, chances are somebody has already encountered the same or a similar issue and will be glad to offer you some advice and assistance.

I ordered one this morning, should have it next week and I'll give it a try..Now I'm curious. I used needle nose pliers to set the spring originally. I used a punch after I ground off the metal below the bend and I was able to seat it completely against the frame.

Was using the punch really all I needed to concentrate the pressure to seat the spring? I can see I'm going to have to pickup another spring to try this out again.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Latest posts

-

-

-

-

Awareness/Mindset/Q&A get together with Bob "Ninja" Porras. Delta/CIA guy. Thursday April 18,2024 (6 Viewers)

- Latest: holesonpaper

-

-

-

Forum statistics

Latest threads

-

-

-

-

Hair-trigger posting... please include more than just the "headline" (2 Viewers)

- Started by Mr H

- Replies: 11

-

-

-

(Duplicate - mods please close) MoCo trans student arrested for threatening school (1 Viewer)

- Started by Lafayette

- Replies: 2