Do you have a different revolver you could try them in?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inconsistent seating depth 38spc LSWC

- Thread starter lazarus

- Start date

The #1 community for Gun Owners of the Northeast

Member Benefits:

No ad networks! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Do you have a different revolver you could try them in?

God I wish. No, sadly not. Pretty sure mine has tight chambers though. My buddy loads 38spc also and some of his loads can be slightly tight in my chambers. Same with factory ammo on occasion, though that almost always is drop in.

Maybe I am nuts, but I think its because lead is usually .001" oversized and that is just enough to cause the tight chambers in the cylinder to be really, really picky how it is loaded.

So I followed John and Mike's advice. I think its from reusing bullets (no, not out of the berm, out of the inertia hammer).

Took apart and reloaded the 40 odd rounds I had left to do.

I used a dozen new bullets discarding the dozen worst bullets that came out of the impact hammer. 100% drop in the cylinders with no crimp at all, so I let it roll. The ~30 reused bullets I loaded the same 6 were varying levels of tight in the chambers with the other ~24 dropping right in.

Those 6 I put progressively more and more crimp on them. 5 of them after just adding a little more crimp went in (2 with some light pressure, 3 dropped in). The last one no matter how much crimp I put on it (well, not enough to crush the case) it wouldn't go in. Dropped about 2/3rds of the way in and stopped. Which was better than the 1/3rd of the way in without.

Took it apart and put a brand new bullet in, with no crimp and it dropped right in to the chamber.

So I think my initial issue was using the WRONG bullet seating step for LSWC. That would have fixed it right there. But I was reusing bullets that some had deformed from the inertia hammer and that was causing me all kinds of issues, especially with the tighter chamber on my revolver seeming to want its rounds fairly perfect without the slightest unevenness/runout.

Only the one round that was just borked 10 ways to Sunday wouldn't drop in my chamber checker.

Thanks everyone for bearing with me and offering advice. Went from feeling like zero after lots of good success with my initial rounds of loading and messing this up (pardon the pun) to on top of the world getting it fixed, working and learning lessons for the future.

I did also order a powder stand for my Lyman powder measure. Just awkward to use it in the T-Mag press. I'll just mount it to my loading bench. Less awkward all around and probably faster to load. Also lets me easily charge a case, put it in the pressure and seat a bullet, rinse and repeat. No loading a tray of cases and then seating a tray of cases. Or rotating the turret back and forth, back and forth (which is fine if I am just trying to load up a few rounds. Slower and a pain trying to load a box of cartridges or something).

Reloading ammunition is a hobby where you never really learn it all. Change firearms or calibers and you start all over again. The best thing I can tell you is to keep good detailed notes. That will keep you from retracing your steps. Don't just keep notes on the ammo, keep notes on the guns preferences for what it likes and what it doesn't. When you get a few extra bucks, buy a Master Chrony chronograph for @ $120. You don't need a super sophisticated chronograph to make better loads.

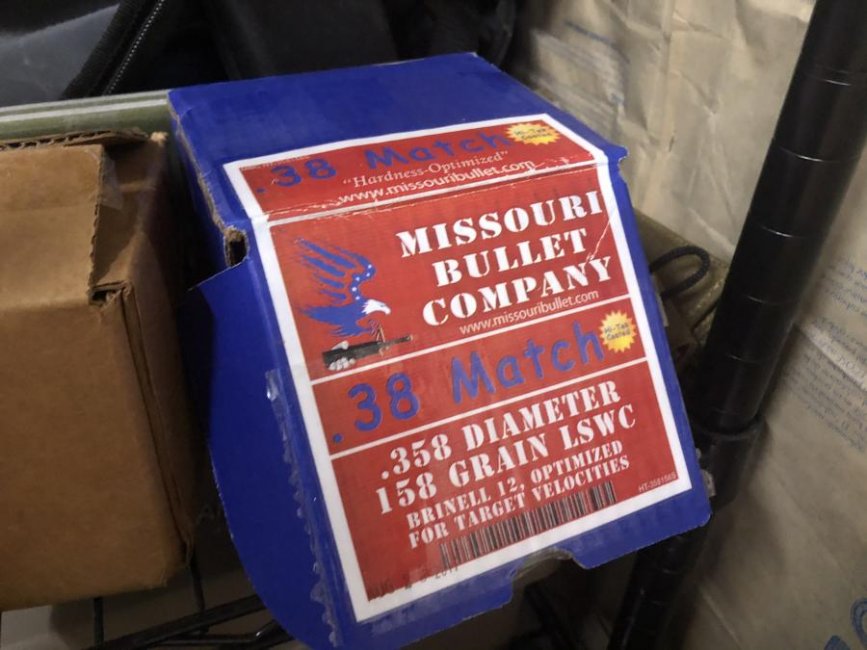

I have loaded exactly the same bullet (Missouri Bullet Company 158gr). I am using the hard cast hitek coated version. When loaded in a mixed lot of brass (some pretty old - i just shot some 30 year old wadcutters loads and was reusing the brass) some are fine, some are a little sticky in the cylinder and some will not chamber at all. What i found was that the hangup was that the base of the bullet was tight in the brass. PMC brass in particular was an issue; i suspect it is a little too thick halfway down the case wall. When you look at the cartridge case you can see the swelling at the back of the bullet. I never see this with either HBWC or soft lead DEWC - i suppose they just swaged down a bit.

Using new Starline brass i have had no issues.

Hope this helps.

Using new Starline brass i have had no issues.

Hope this helps.

On your particular SWC's , when seated properly in the crimping grove, is the shoulder of the bullet extended beyond the case ? ( This would Not be an inherently bad thing . In fact it is a positive design feature .)

BUT , if your Throat is undersized , the cartridge would not chamber properly . The field expedient way to check , is a bullet should pass through the throat with no more than light finger pressure .

If not , two possibilities - The throat could be indeed undersized , or the bullet sizing could be inconsistent , with at least some of the bullets oversize .

What is the nominal diameter of your bullets ? .358 is the most common, and usually correct diameter for .38/357 cast bullets . Use your micrometer , and check the actual diameter of a meaningful same of your bullets . If you are feeling really froggy , measure the diameter of all your throats ( worth a discussion of its own .

Field Expedient method to use up your existing stash of bullets , in your revolver as-is : Seat the bullets deeper in the case , so than you are crimping over the front shoulder rather than the crimp groove .

IF the bullets are either inconsistent , or larger dia than listed on box/ advertised , that would be grounds for a refund . Or to skip a potential hassle , use your existing supply crimped over the shoulder , and use a different supplier for your next batch . Unless you are planned otherwise to persue bullet casting , or you have multiple thousands of bullets in question , probably not worthwhile to resize them yourself .

OR , if the throats are indeed undersized , the proper step is to ream all the throats to a consistent size, typically .3585 to .359 . Correcting undersized/ inconsistent throats will usually result in significant accuracy improvement .

I haven’t checked the throats yet. The cases are seated with a few tenths Of the shoulder exposed from the case at 1.455” COAL. Unmolested bullets measure in at .3585” across half a dozen. One was basically .3587” and one was just about spot on .358, but the rest all measured right at .3585”

.358” lead plus the coating is my guess?

Molested bullets measured from .358 to .3593 measuring across a dozen of them.

Attachments

Reloading ammunition is a hobby where you never really learn it all. Change firearms or calibers and you start all over again. The best thing I can tell you is to keep good detailed notes. That will keep you from retracing your steps. Don't just keep notes on the ammo, keep notes on the guns preferences for what it likes and what it doesn't. When you get a few extra bucks, buy a Master Chrony chronograph for @ $120. You don't need a super sophisticated chronograph to make better loads.

I went Caldwell basic as I tracked one down for $50. Seems to work well so far.

Also thanks for all of your help.

Anytime.

BTW, your bullet looks good.

BTW, your bullet looks good.

I have loaded exactly the same bullet (Missouri Bullet Company 158gr). I am using the hard cast hitek coated version. When loaded in a mixed lot of brass (some pretty old - i just shot some 30 year old wadcutters loads and was reusing the brass) some are fine, some are a little sticky in the cylinder and some will not chamber at all. What i found was that the hangup was that the base of the bullet was tight in the brass. PMC brass in particular was an issue; i suspect it is a little too thick halfway down the case wall. When you look at the cartridge case you can see the swelling at the back of the bullet. I never see this with either HBWC or soft lead DEWC - i suppose they just swaged down a bit.

Using new Starline brass i have had no issues.

Hope this helps.

Thanks! Visually I think that’s what I am seeing. None are bad now. These are their softer lead coated LSWC. But when crimping down it seems to mush the bullet (or case) towards the rear just a hair and I think that was an early issue when there was too much crimp. I wish I could say it was one head stamp, but I saw it with PPU, federal and Winchester brass. Also nickel coated cases. But I think my original son was using the wrong bullet seating stem and it was inconsistent or damaging the bullets in seating.

Anytime.

BTW, your bullet looks good.

This looks better :-) (well, to my mind)

Attachments

Nice looking Colt. I remember they had a very smooth action.

Mine mostly does. Timings a little off. I’ve got the DA guide to colts coming along with a new hand. Shaving a tiny bit of lead in SA once or twice per revolution and a little hang up cocking they hammer once around.

Not positive I can lengthen the existing hand. But hoping I can just peen the existing hand slightly and get it back in time. But want a new one on hand in case it looks like it’s already been worked on (can’t recall what it looked like when I had the side plate off)

Incredibly smooth in DA and very smooth trigger.

Not positive I can lengthen the existing hand. But hoping I can just peen the existing hand slightly and get it back in time. But want a new one on hand in case it looks like it’s already been worked on (can’t recall what it looked like when I had the side plate off)

Incredibly smooth in DA and very smooth trigger.

Biggfoot44

Ultimate Member

- Aug 2, 2009

- 33,139

Perhaps the tolerance stack of the extra .0005 dia from the bullet coating , and Colt throat dia @ minimum . ( Old school Colts had bore dia of .356 vs .357 for S&W . )

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Latest posts

Forum statistics

Latest threads

-

-

-

Hair-trigger posting... please include more than just the "headline" (2 Viewers)

- Started by Mr H

- Replies: 11

-

-

-

(Duplicate - mods please close) MoCo trans student arrested for threatening school

- Started by Lafayette

- Replies: 2

-