shershot99

Active Member

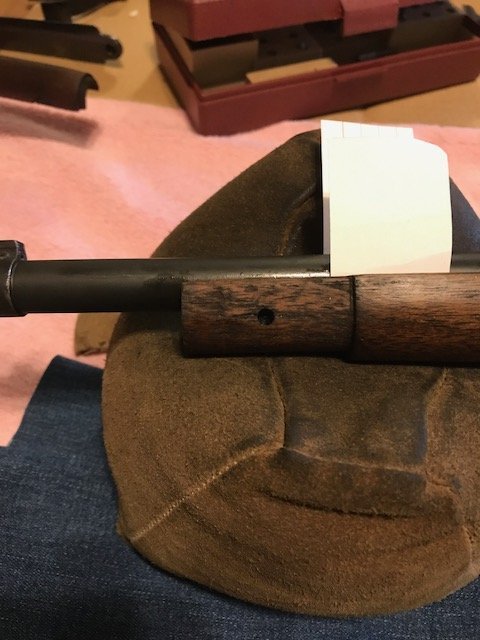

Hello. I obtained a 1903A3 from my uncle when he passed away. It had an original stock (straight stock) on it but also an unfinished C stock. I would really like to "finish" the C stock and mount the barreled action onto it. the problem I have is that I am not sure if he fully finished fitting the action to the stock and just never applied the finish to it. If I mount all the metal, how can I tell for sure that the stock is fitted correctly before I proceed to apply a finish to the wood? Any thoughts? I would like to do this myself if I can as opposed to sending it to the CMP or a local gunsmith that would specialize in these types of rifles (any thoughts on good local gunsmiths that work with US WW2 guns would be great too).

Thanks all.

Rick

Thanks all.

Rick

![InkedIMG_1051[4397]_LI.jpg InkedIMG_1051[4397]_LI.jpg](https://www.mdshooters.com/data/attachments/221/221673-93cfb25428a66bc83644603df27fa117.jpg)