cyclops

Active Member

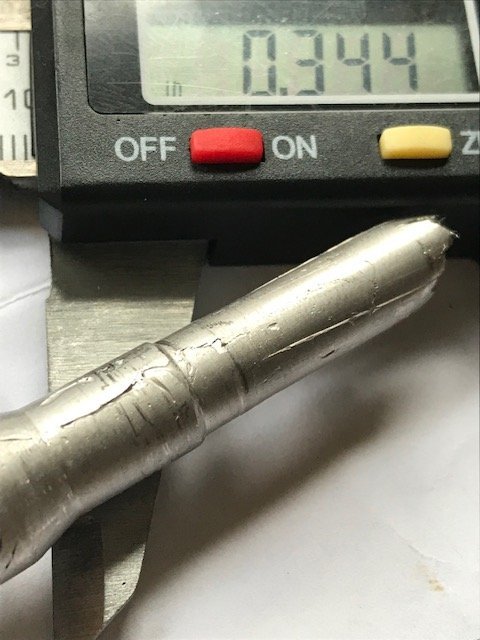

I like that PMA tool. Had never heard of them. I have a 21st century that I run on my mini lathe and it does an awesome job. Had a bunch of 17 fireball made from 5.56 and the necks were .017". Turned them down pretty quick

Not trying to take this thread in a different direction or make a plug for anything just relating my experience. Having used both the 21st century and the PMA neck turners my experience has been the PMA is easier to set up with it's mandrel adjuster as opposed to the 21st's cutter adjuster. I usually set my initial neck thickness with a feeler gauge and then trial turn and measure. My 21st has what I consider to be a good bit of lash in the adjuster screw mechanism so for me it's tedious and sometimes a bit frustrating when I try to make a fine adjustment . My PMA is much better in this regard. So I have set my 21st at the thickness I want for one particular case and have locked it down and I leave it alone. I basically use it for one caliber/case. The PMA I use for other brass cases I neck turn.