smores

Creepy-Ass Cracker

Ok, I'm going to be threading, contouring, chambering etc. a .300/221 barrel to my AR-15 barrel extension this week and I have a few questions about the contour of the barrel.

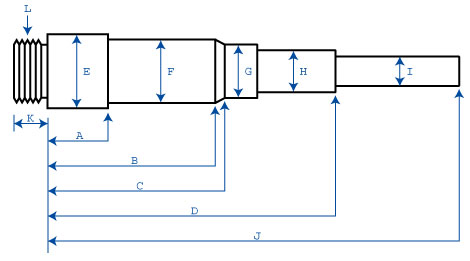

Below is the contour diagram I found at Shilen's website:

My main concern are dimensions D, E, F and H.

What is the correct measurement (D) for a pistol-length gas system?

Secondly, what barrel diameter is correct (E, F) for .300/221 or can I follow the standard contour? Once I determine the proper diameter for H, the rest of the barrel will follow that diameter until the muzzle where a .308 Phantom flash hider will be installed.

For (H) under the gas block, the diagram shows the barrel diameter should be .760", yet the gas block I have from JP Enterprises is supposedly .750". I guess since it's a clamp-on type, a difference in .010" won't be that big of a deal. I guess I can measure the ID of the gas block when I get home and go from there. Any advice?

As for the gas port, I decided I'm going to just drill it then ream it to the proper diameter after speaking with someone very knowledgeable about accurate AR barrels.

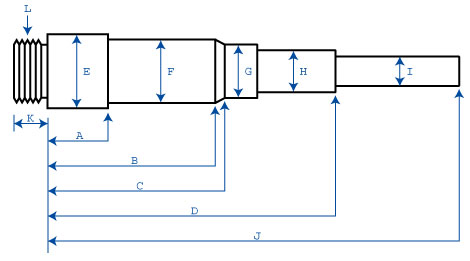

Below is the contour diagram I found at Shilen's website:

My main concern are dimensions D, E, F and H.

What is the correct measurement (D) for a pistol-length gas system?

Secondly, what barrel diameter is correct (E, F) for .300/221 or can I follow the standard contour? Once I determine the proper diameter for H, the rest of the barrel will follow that diameter until the muzzle where a .308 Phantom flash hider will be installed.

For (H) under the gas block, the diagram shows the barrel diameter should be .760", yet the gas block I have from JP Enterprises is supposedly .750". I guess since it's a clamp-on type, a difference in .010" won't be that big of a deal. I guess I can measure the ID of the gas block when I get home and go from there. Any advice?

As for the gas port, I decided I'm going to just drill it then ream it to the proper diameter after speaking with someone very knowledgeable about accurate AR barrels.