You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AR-15 barrel: Chrome vs. Melonite?

- Thread starter chooks9

- Start date

The #1 community for Gun Owners of the Northeast

Member Benefits:

No ad networks! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

fa18hooker

99-9X

Melonite (Salt Bath Nitriding) will vastly increase the hardness of the barrel, without changing a single dimension. Chroming a barrel will increase the internal dimensions of the barrel, which is why a chrome-lined barrel will usually be less accurate (they have to actually over-bore the barrel to allow for the dimensions of the chrome lining). Salt Bath Nitrided barrels that I have shot have lasted over 6k rounds with match accuracy (across-the-course shooting out to 600 yards). Chrome lined barrels are normally reserved for less accurate applications that require extended durability (combat arms, etc). One major consideration is that a SBN barrel is supposed to be "shot in" before you have it done...after it's done, there is absolutely no opportunity to fix any mistakes (a rough bore, a short chamber, etc). You also can't set back a SBN barrel (i.e. cut it back and rechamber it when the throat erodes).

240 towles

master of puppets

Melonite (Salt Bath Nitriding) will vastly increase the hardness of the barrel, without changing a single dimension. Chroming a barrel will increase the internal dimensions of the barrel, which is why a chrome-lined barrel will usually be less accurate (they have to actually over-bore the barrel to allow for the dimensions of the chrome lining). Salt Bath Nitrided barrels that I have shot have lasted over 6k rounds with match accuracy (across-the-course shooting out to 600 yards). Chrome lined barrels are normally reserved for less accurate applications that require extended durability (combat arms, etc). One major consideration is that a SBN barrel is supposed to be "shot in" before you have it done...after it's done, there is absolutely no opportunity to fix any mistakes (a rough bore, a short chamber, etc). You also can't set back a SBN barrel (i.e. cut it back and rechamber it when the throat erodes).

Thanks for the info...It sounds like Melonite would be sufficient but the chrome seems to be a better option if I am expecting longer barrel life.

I have a melonite barrel on an early Spikes/Adams piston upper. It is very accurate. I also have one on my LWRC REPR. It was not so accurate and was rough on the inside. Two Tubb final finish kits fixed the REPR barrel, but it was slow going and shredded the jackets on some of the first FF rounds. I am fully satisfied with the end result which is .6 moa.

fa18hooker is right on the money with his advice.

fa18hooker is right on the money with his advice.

240 towles

master of puppets

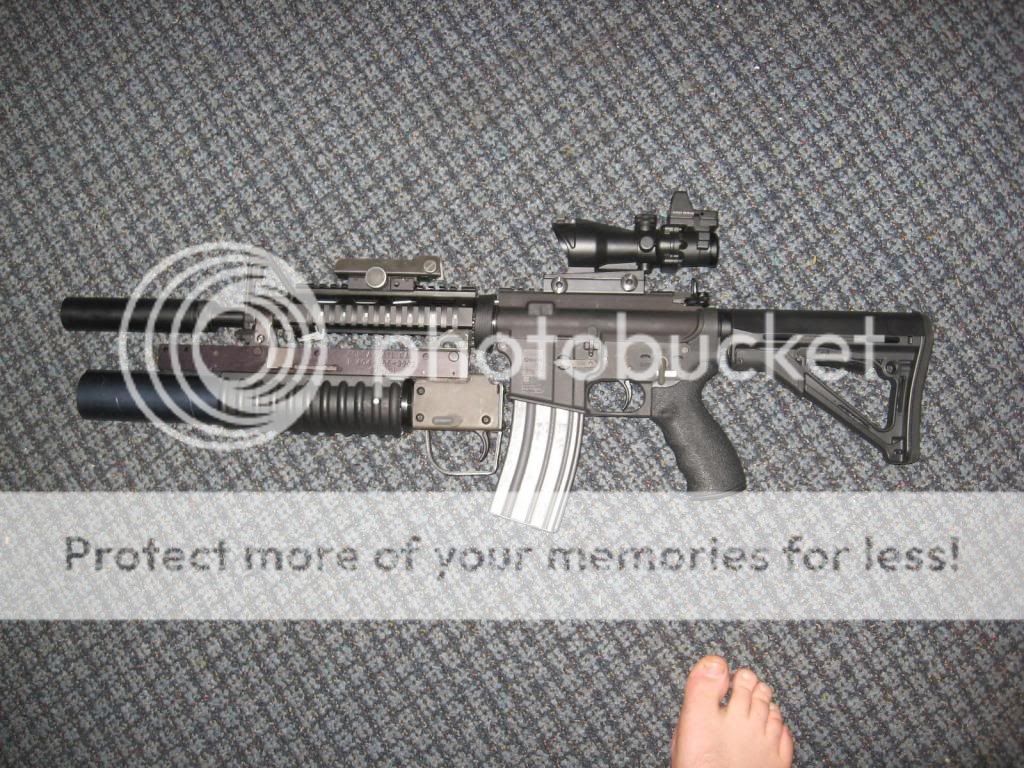

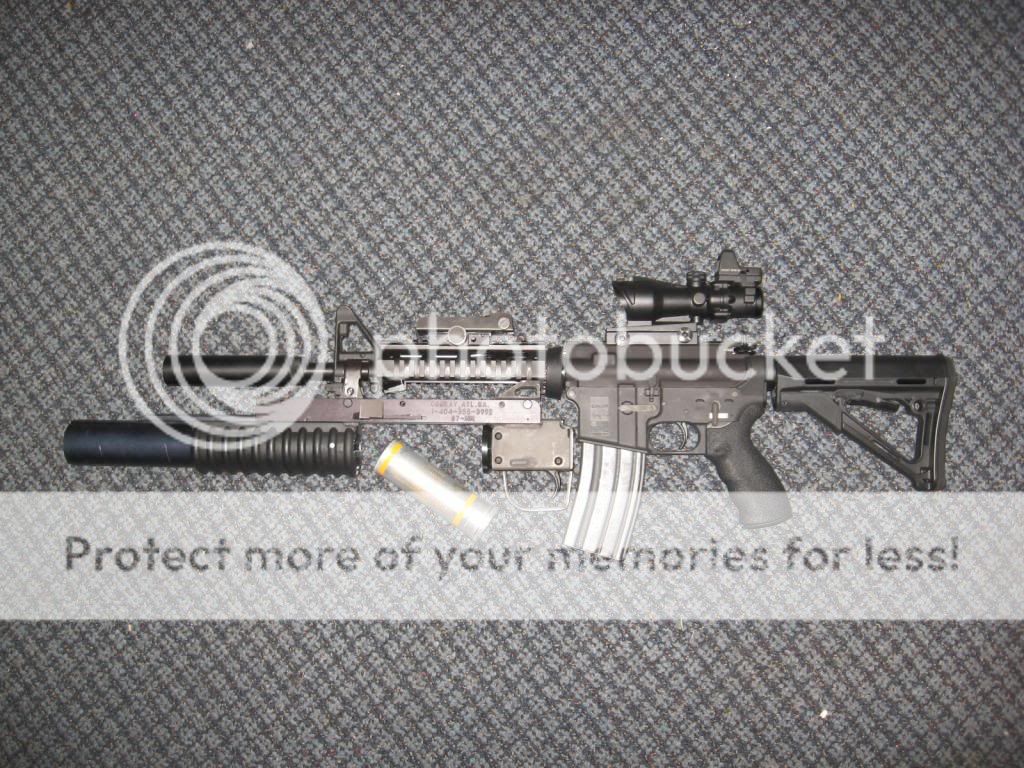

thanks, I took a long time to get into 37mm, but when I went in, I went in hard.

fa18hooker is right on the money with his advice.

I know what his range time involves, and anyone who ignores his advice is an idiot.

amoebicmagician

Samopal Goblin

okay, so here is the deal:

Melonite is EXTREMELY hard, or rather, the nitriding process makes the steel extremely hard, depending on chromium, molybdenum, vanadium, and other carbide forming alloying elements you can end up with a Rockwell C hardness of anywhere between 62-72, which is INCREDIBLY HARD. Hardened Martensitic Tool Steel is about HRC 60.

So, the deal here is this: The nitriding process will actually make the barrel's surface harder than Chrome down to as much as 1.5mm depending on the carbon content of the steel prior to nitriding.

Chrome lining in barrels is usually much thicker than this, especially in barrels that are cold hammer forged around a mandrel with the chrome already inside the barrel blank before hammering.

Now, there has been all kinds of research into this that says that Nitrided finishes, of which Melonite (QPQ, or Quench Polish Quench) is the best known other than the revised Tenifer process which was until recently a nitrocarburizing process, which is different than nitriding. The research says that Nitrided barrel steel is slightly harder, slightly more corrosion resistant, and in possession of slightly more natural lubricity than Hard chrome, as well as supposedly offering better accuracy than chrome lined barrels.

Now, while that might be true from a certain point of view, I will give you my two cents.

There is nothing wrong with Nitriding, but frankly, I tend to go with what has a track record of working in the real world. I have SKSs that have had their chrome lined barrels shot to the living end before being sent to me, at which point I proceeded to shoot them to the living end, while not taking very much care to clean them, and shooting primarily surplus ammo from the Saudi Department of the Interior that I've had stockpiled since the late 90s which is corrosive Berdan primed.

The bores look FANTASTIC, even after all this time, and all this use, even after sitting warehoused after being shot with corrosive ammo for decades. Slugging the bore, even after all these rounds the bore at the muzzle measures .31182 and the bore shines like silver.

I can attest that Nitrided barrels are EXTREMELY hard on the surface, and that in the short term at least they seem to perform as advertised. Glock Tenifer and Melonite are simlar in the end result surface they end up leaving behind, and I've never been able to shoot out a glock barrel or make one rust. However, the Glock Nitrocarburizing Tenifer treatment soaks into the metal a long way further than the surface hardening treatment on Melonite QPQ process, and the carbon content of the metal makes a big difference in how deep the nitriding goes into the metal.

I will say that a few of my friends have gotten their custom rifled barrels melonite treated after shooting them until they were shooting the way they wanted, with the hopes of super hardening the bore and freezing the bore in that shootable state.

Some of the barrels came back shooting great, some did not, and some shot okay other than a perceivable shift in POI.

When chrome lining was in it's infancy there was much more accuracy difference between plain steel or stainless barrels and chrome lined barrels than there are today. Cold hammer forged chrome lined barrels shoot so well compared to stainless barrels that the difference is honestly not even worth mentioning unless a quarter inch at 150-200 yards is a big deal to you.

My main beef with the nitriding is that I haven't seen these things stand the test of time, and I am afraid that since the layer of super hardened nitrided steel is so thin, that it will be eroded much quicker than a good chrome lining despite it being SUPER hard.

Then again, as I've said, I've never seen a shot out glock barrel.

I'd say that if it's done by a good and reputable business, then either is fine. I just prefer chrome because it's treated me so well for so long. I mean, Chromium is what they add to make steel into stainless steel, the stuff just WORKS.

Mossberg made a polygonal rifled AR barrel that was melonite coated to nearly 70 HRC hardness that was relatively cheap and was getting AMAZING reviews from people doing torture tests on it. People who usually will not use a 1-7 twist rifled barrel were buying these things because the polygonal rifling plus the incredible hardness of the bore were causing the barrel to be nearly impossible to shoot out. I'm usually not a big fan of the 1-7, preferring a 1-9 for barrel longevity. However, if they can put one of the barrels on their 'dealer sample' M-4s and it cleans up like new, and guages like new after 10,000 rounds of full auto? I think I'm a believer.

Melonite is EXTREMELY hard, or rather, the nitriding process makes the steel extremely hard, depending on chromium, molybdenum, vanadium, and other carbide forming alloying elements you can end up with a Rockwell C hardness of anywhere between 62-72, which is INCREDIBLY HARD. Hardened Martensitic Tool Steel is about HRC 60.

So, the deal here is this: The nitriding process will actually make the barrel's surface harder than Chrome down to as much as 1.5mm depending on the carbon content of the steel prior to nitriding.

Chrome lining in barrels is usually much thicker than this, especially in barrels that are cold hammer forged around a mandrel with the chrome already inside the barrel blank before hammering.

Now, there has been all kinds of research into this that says that Nitrided finishes, of which Melonite (QPQ, or Quench Polish Quench) is the best known other than the revised Tenifer process which was until recently a nitrocarburizing process, which is different than nitriding. The research says that Nitrided barrel steel is slightly harder, slightly more corrosion resistant, and in possession of slightly more natural lubricity than Hard chrome, as well as supposedly offering better accuracy than chrome lined barrels.

Now, while that might be true from a certain point of view, I will give you my two cents.

There is nothing wrong with Nitriding, but frankly, I tend to go with what has a track record of working in the real world. I have SKSs that have had their chrome lined barrels shot to the living end before being sent to me, at which point I proceeded to shoot them to the living end, while not taking very much care to clean them, and shooting primarily surplus ammo from the Saudi Department of the Interior that I've had stockpiled since the late 90s which is corrosive Berdan primed.

The bores look FANTASTIC, even after all this time, and all this use, even after sitting warehoused after being shot with corrosive ammo for decades. Slugging the bore, even after all these rounds the bore at the muzzle measures .31182 and the bore shines like silver.

I can attest that Nitrided barrels are EXTREMELY hard on the surface, and that in the short term at least they seem to perform as advertised. Glock Tenifer and Melonite are simlar in the end result surface they end up leaving behind, and I've never been able to shoot out a glock barrel or make one rust. However, the Glock Nitrocarburizing Tenifer treatment soaks into the metal a long way further than the surface hardening treatment on Melonite QPQ process, and the carbon content of the metal makes a big difference in how deep the nitriding goes into the metal.

I will say that a few of my friends have gotten their custom rifled barrels melonite treated after shooting them until they were shooting the way they wanted, with the hopes of super hardening the bore and freezing the bore in that shootable state.

Some of the barrels came back shooting great, some did not, and some shot okay other than a perceivable shift in POI.

When chrome lining was in it's infancy there was much more accuracy difference between plain steel or stainless barrels and chrome lined barrels than there are today. Cold hammer forged chrome lined barrels shoot so well compared to stainless barrels that the difference is honestly not even worth mentioning unless a quarter inch at 150-200 yards is a big deal to you.

My main beef with the nitriding is that I haven't seen these things stand the test of time, and I am afraid that since the layer of super hardened nitrided steel is so thin, that it will be eroded much quicker than a good chrome lining despite it being SUPER hard.

Then again, as I've said, I've never seen a shot out glock barrel.

I'd say that if it's done by a good and reputable business, then either is fine. I just prefer chrome because it's treated me so well for so long. I mean, Chromium is what they add to make steel into stainless steel, the stuff just WORKS.

Mossberg made a polygonal rifled AR barrel that was melonite coated to nearly 70 HRC hardness that was relatively cheap and was getting AMAZING reviews from people doing torture tests on it. People who usually will not use a 1-7 twist rifled barrel were buying these things because the polygonal rifling plus the incredible hardness of the bore were causing the barrel to be nearly impossible to shoot out. I'm usually not a big fan of the 1-7, preferring a 1-9 for barrel longevity. However, if they can put one of the barrels on their 'dealer sample' M-4s and it cleans up like new, and guages like new after 10,000 rounds of full auto? I think I'm a believer.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)