You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom CNC Grips

- Thread starter jcarpenter

- Start date

The #1 community for Gun Owners of the Northeast

Member Benefits:

No ad networks! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

That really gives me one more reason why I need a CNC. Nicely done!

jcarpenter

Member

Thanks!

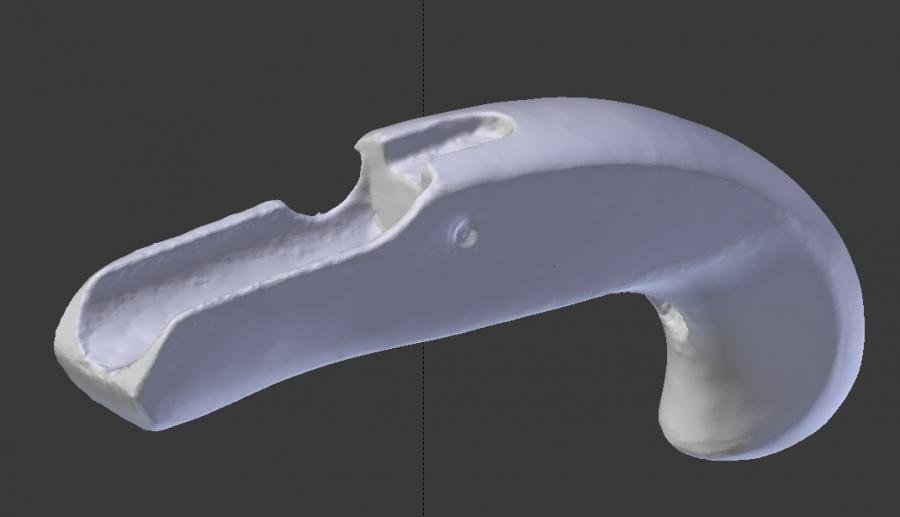

I use Solidworks or Blender to model the shape of the grip. Then I use Deskproto to add the checkering toolpaths and generate the G Code. Starting to do 3D scans of BP pistols stocks so I can replicate them on the CNC. Below is a STL model of a BP pistol I have scanned. Once they are an STL format file Deskproto can generate the G Code.

I use Solidworks or Blender to model the shape of the grip. Then I use Deskproto to add the checkering toolpaths and generate the G Code. Starting to do 3D scans of BP pistols stocks so I can replicate them on the CNC. Below is a STL model of a BP pistol I have scanned. Once they are an STL format file Deskproto can generate the G Code.

Attachments

StantonCree

Watch your beer

- Jan 23, 2011

- 23,932

So freaking cool!! I love threads like this on what some of you all build!!!

What wood did you use?

What wood did you use?

mxrider

Former MSI Treasurer

Do these require a 5 axis cnc? We have a 5' X 12' 3 axis and wondering if it could do this type of work. Using Enroute currently and importing .dxf from Autocad

Sent from my SM-G920V using Tapatalk

Sent from my SM-G920V using Tapatalk

johnnyb2

Ultimate Member

Those are some GREAT looking grips. I wish I had the talent, ( and machinery :-) to do that kind of work as I used to love working with my hands when I owned a house. Now, with an apt, no room for that kind of work. But they look absolutely professional and well made. GREAT JOB!!

jcarpenter

Member

Wow! Thanks for all the encouragement. I am just starting to play with this stuff.

trailtoy: Not doing grips commercially yet and don't even know if it will be possible. Custom artwork for the checkering and the CNC cutting take about 8 hours. And that assumes the 3D model of the grip already exists. Just doing a few here and there to get my feet wet.

mpdc4511: Wood is cocobolo and had to build an enclosure around the router to keep the dust out of my lungs.

mxrider: The CNC router is a really high quality 10 inch x 12 inch x 4 inch 3 axis router. To do checkering your CNC needs to be repeatable to one or two thousanths. But try it and see!

John C

trailtoy: Not doing grips commercially yet and don't even know if it will be possible. Custom artwork for the checkering and the CNC cutting take about 8 hours. And that assumes the 3D model of the grip already exists. Just doing a few here and there to get my feet wet.

mpdc4511: Wood is cocobolo and had to build an enclosure around the router to keep the dust out of my lungs.

mxrider: The CNC router is a really high quality 10 inch x 12 inch x 4 inch 3 axis router. To do checkering your CNC needs to be repeatable to one or two thousanths. But try it and see!

John C

Thanks!

I use Solidworks or Blender to model the shape of the grip. Then I use Deskproto to add the checkering toolpaths and generate the G Code. Starting to do 3D scans of BP pistols stocks so I can replicate them on the CNC. Below is a STL model of a BP pistol I have scanned. Once they are an STL format file Deskproto can generate the G Code.

What tool do you use to scan and how much detail can it pickup?

I building my own tabletop CNC and my first project was going to finish an 80% lower.

https://www.mdshooters.com/showthread.php?t=196818

Now after seeing those grips the wheels are turning even faster. Being able to scan stuff in 3D could really be great for getting a design idea moving.

Sent from my iPhone using Tapatalk

jcarpenter

Member

ToolAA,

I use photogrammetry to scan 3D objects. That is where you take a bunch of pictures around an object and then a software program like Agisoft Photoscan reads the pictures and generates a 3D model. You then usually have to clean up the scanned model a bit before you export as an STL file for 3D printing or G Code generation for CNC routing. Level of detail is the resolution of your camera. My camera has 6K points horizontal. So if the object just fits in the viewer and is 6 inches wide then the possible resolution is one thousandth. Theoretically. At my beginning skill level it is more like 0.062.

John C

I use photogrammetry to scan 3D objects. That is where you take a bunch of pictures around an object and then a software program like Agisoft Photoscan reads the pictures and generates a 3D model. You then usually have to clean up the scanned model a bit before you export as an STL file for 3D printing or G Code generation for CNC routing. Level of detail is the resolution of your camera. My camera has 6K points horizontal. So if the object just fits in the viewer and is 6 inches wide then the possible resolution is one thousandth. Theoretically. At my beginning skill level it is more like 0.062.

John C

Awesome work. that is amazing looking.

ToolAA,

I use photogrammetry to scan 3D objects. That is where you take a bunch of pictures around an object and then a software program like Agisoft Photoscan reads the pictures and generates a 3D model.

John C

This is good info the standard edition seems reasonably priced.

Sent from my iPhone using Tapatalk

jcarpenter

Member

ToolAA,

I took a short photography class at Carroll Community and used my student number to buy the academic version from Agisoft. That is very reasonably priced. The real problem is not software, it is taking pictures that capture the data you need correctly. For grips there is the problem that polymer take lousy pictures. I gave up 3D scanning on the grips above and just drew it up in CAD. Grips are not really organic shapes and lend themselves to CAD. More on my photogrammetry at: http://carpenterswoodworking.com/?page_id=665

John C

I took a short photography class at Carroll Community and used my student number to buy the academic version from Agisoft. That is very reasonably priced. The real problem is not software, it is taking pictures that capture the data you need correctly. For grips there is the problem that polymer take lousy pictures. I gave up 3D scanning on the grips above and just drew it up in CAD. Grips are not really organic shapes and lend themselves to CAD. More on my photogrammetry at: http://carpenterswoodworking.com/?page_id=665

John C

Last edited:

John that link to your blog is a great site. I just bookmarked it and will be spending more time reading after work.

My wife is a teacher so i think she would qualify for the edu version.

Im also interested in the cnc you are building if you post any photos I'd love to see them.

If you ever need something 3d printed maybe i can help out. I just built a printer a few months ago.

Sent from my iPhone using Tapatalk

My wife is a teacher so i think she would qualify for the edu version.

Im also interested in the cnc you are building if you post any photos I'd love to see them.

If you ever need something 3d printed maybe i can help out. I just built a printer a few months ago.

Sent from my iPhone using Tapatalk

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Latest posts

-

-

-

-

-

‘Why is nothing being done?’: Concerns grow about drug use, fighting in Montgomery Co. school bathrooms (13 Viewers)

- Latest: RFBfromDE

-

Forum statistics

Latest threads

-

‘Why is nothing being done?’: Concerns grow about drug use, fighting in Montgomery Co. school bathrooms (13 Viewers)

- Started by RFBfromDE

- Replies: 0

-

-

-

-

-

-

Hair-trigger posting... please include more than just the "headline" (1 Viewer)

- Started by Mr H

- Replies: 13