I think it was the discussions in Doc's brass thread that got me thinking about sorting cases by water capacity in grains. I'm in the middle of a project where I was about to sort by head stamp and case weight, like I've always done when reloading for more than just range fun. Reading several opinions in Doc's thread (advocating that sorting by water capacity weight is more accurate) started me wondering if I've been wasting my time all these years. Many outdoor writers these days will point out that case capacity (measured in grains of water) is more accurate than sorting the way I do. I don't know if these water capacity tests are widespread or if people are simply opining with, well ... opinions.  Personally, I've never tried this before.

Personally, I've never tried this before.

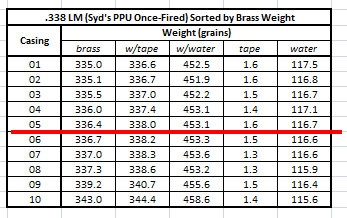

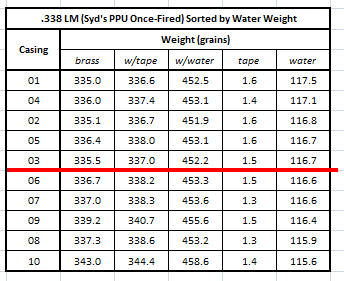

So anyway, I'm working quite a bit with .338 Lapua Magnum at the moment, so figured focusing on that cartridge wouldn't take me too far away from what I'm already doing. Of the brass I've used for reloading .338, PPU seems to be the least consistent by any measure; considering weight, neck thickness/uniformity, and firing stretch deltas, everything about this brass is more erratic than the other brass I've loaded in .338. Admittedly, the brands I use cost more, much more. If fact, the only reason I have PPU brass is that I picked up some of Syd’s Ammo hand loads at a show earlier this year and he used PPU. So that's what I plan on using here.

I guess the most meaningful measure is accuracy and consistency of bullets at the muzzle and at applicable distances downrange. But for what I'm planning to do here today, I'm limiting the scope to "sorting brass by weight versus sorting by water capacity weight" to determine whether the two different methods of sorting would result in different groups (of 5), for 5-round load development and/or accuracy tests: If I sort 10 cases by weight and separated them into two 5-round groups, then sort the same 10 cases by water capacity weight, will I end up with two different 5-round groups? If the answer is "no", then I might not explore this topic any further. If yes (or if I notice any anomalies in the data I collect), then maybe another science project out on the range is in order.

I'll come back on and post again when I get some results.

Personally, I've never tried this before.

Personally, I've never tried this before.So anyway, I'm working quite a bit with .338 Lapua Magnum at the moment, so figured focusing on that cartridge wouldn't take me too far away from what I'm already doing. Of the brass I've used for reloading .338, PPU seems to be the least consistent by any measure; considering weight, neck thickness/uniformity, and firing stretch deltas, everything about this brass is more erratic than the other brass I've loaded in .338. Admittedly, the brands I use cost more, much more. If fact, the only reason I have PPU brass is that I picked up some of Syd’s Ammo hand loads at a show earlier this year and he used PPU. So that's what I plan on using here.

I guess the most meaningful measure is accuracy and consistency of bullets at the muzzle and at applicable distances downrange. But for what I'm planning to do here today, I'm limiting the scope to "sorting brass by weight versus sorting by water capacity weight" to determine whether the two different methods of sorting would result in different groups (of 5), for 5-round load development and/or accuracy tests: If I sort 10 cases by weight and separated them into two 5-round groups, then sort the same 10 cases by water capacity weight, will I end up with two different 5-round groups? If the answer is "no", then I might not explore this topic any further. If yes (or if I notice any anomalies in the data I collect), then maybe another science project out on the range is in order.

I'll come back on and post again when I get some results.