Mark K

Active Member

I haven't found much guidance on how much to taper a casing neck, other than words to the effect of "until it's how you like it."

My wife recently got a Glock 42, and we've been breaking it in. I'm now experimenting with 100-gr FMJ reloads (considering the supply situation these days).

I've been having a bit of a problem with feeding -- rounds occasionally getting caught up at a 45-angle between the magazine and the chamber, requiring the mag to be dropped to clear it. Someone at the gun club suggested that I maybe wasn't tapering the case necks enough after seating the bullets, and the edges were catching up on the feed ramp.

I've always tried to taper as little as possible, just enough to hold the bullet. The guy recommended tapering it in about half the thickness of the brass -- so he could feel the edge on his fingernail, but so it wouldn't catch on the nail. Does that sound right? His reloads were certainly tapered more than mine were.

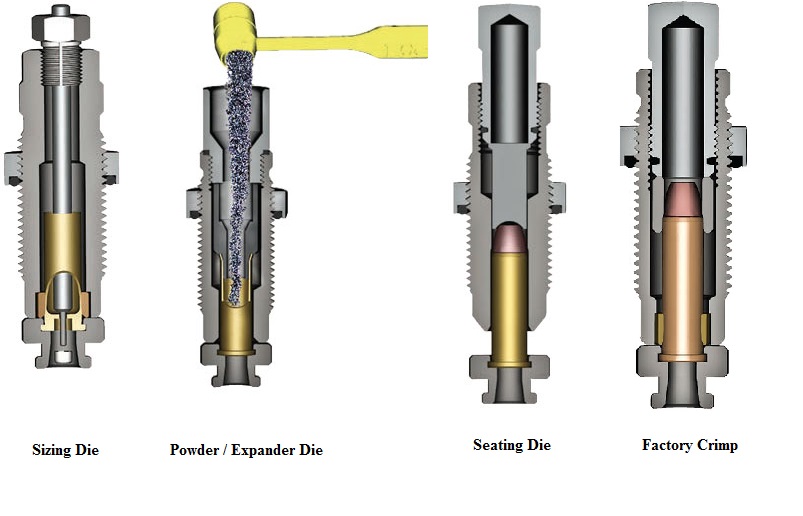

So what's the correct drill when using a bullet-seating and taper die (Lee in my case)? Get the COL first, then adjust for taper?

My wife recently got a Glock 42, and we've been breaking it in. I'm now experimenting with 100-gr FMJ reloads (considering the supply situation these days).

I've been having a bit of a problem with feeding -- rounds occasionally getting caught up at a 45-angle between the magazine and the chamber, requiring the mag to be dropped to clear it. Someone at the gun club suggested that I maybe wasn't tapering the case necks enough after seating the bullets, and the edges were catching up on the feed ramp.

I've always tried to taper as little as possible, just enough to hold the bullet. The guy recommended tapering it in about half the thickness of the brass -- so he could feel the edge on his fingernail, but so it wouldn't catch on the nail. Does that sound right? His reloads were certainly tapered more than mine were.

So what's the correct drill when using a bullet-seating and taper die (Lee in my case)? Get the COL first, then adjust for taper?