aps410

Member

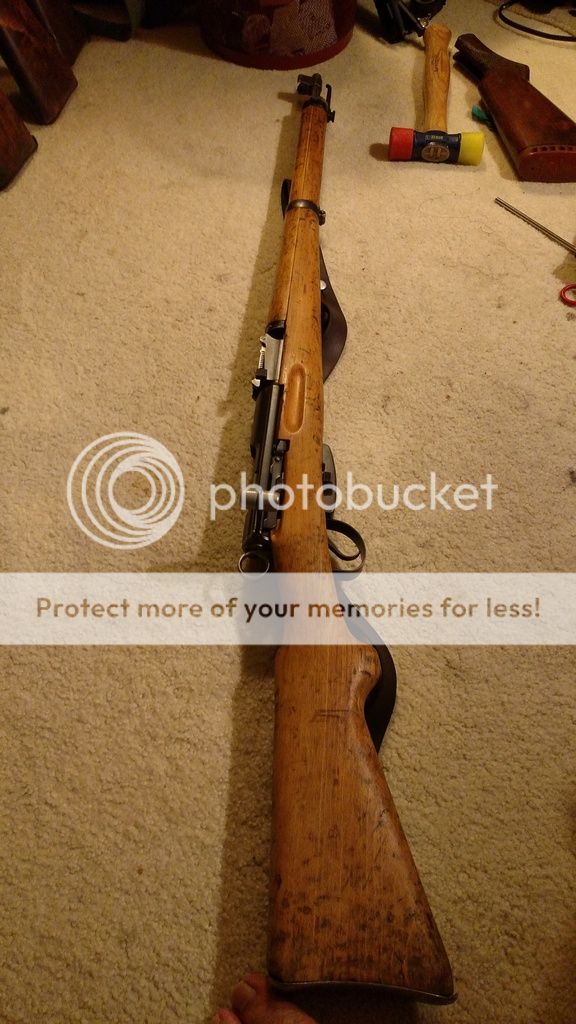

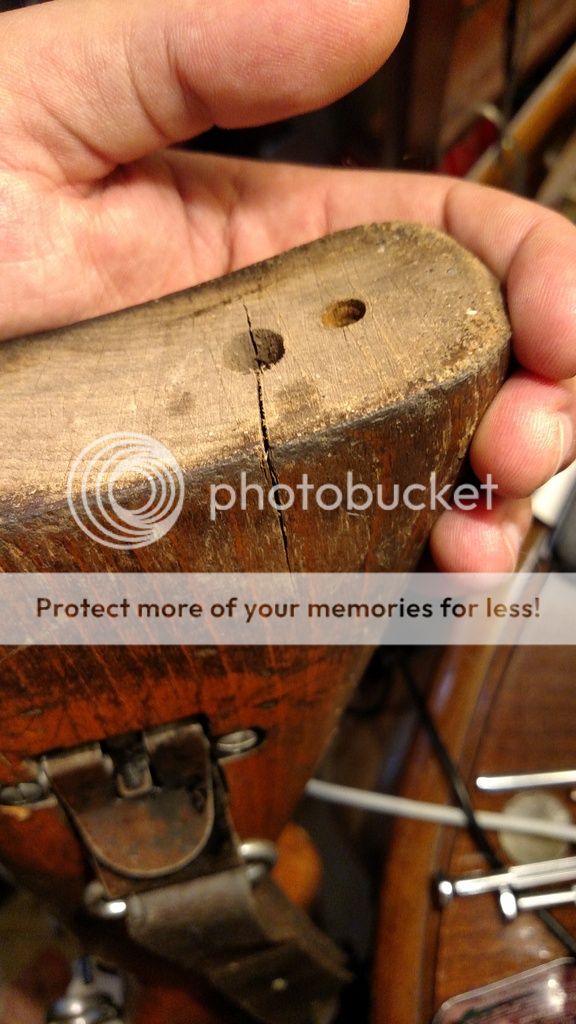

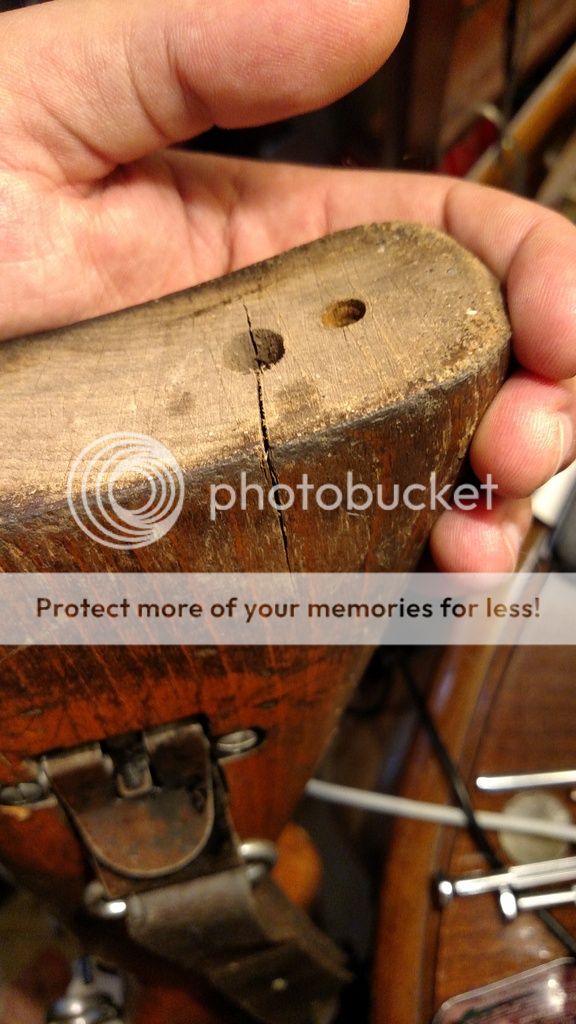

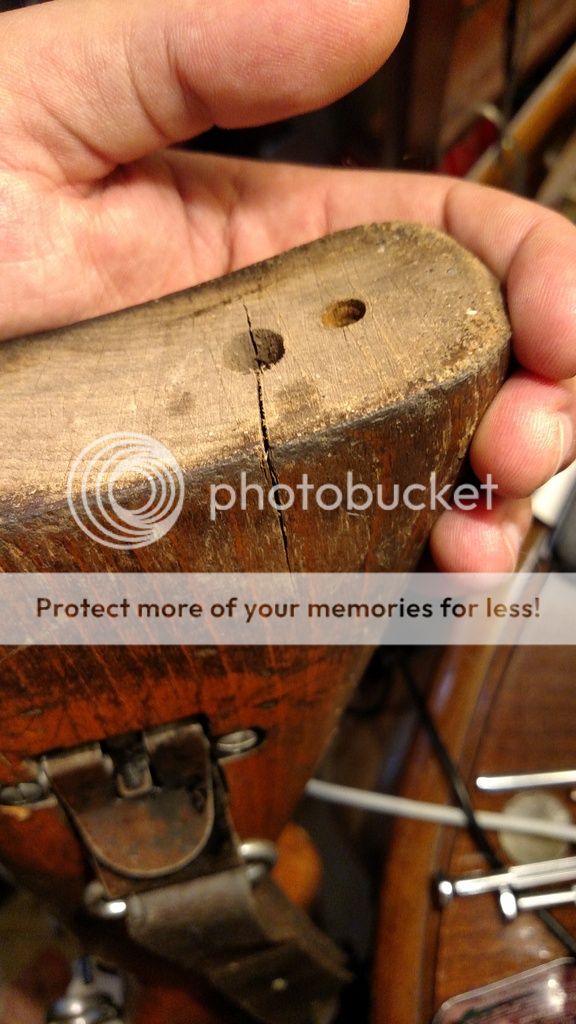

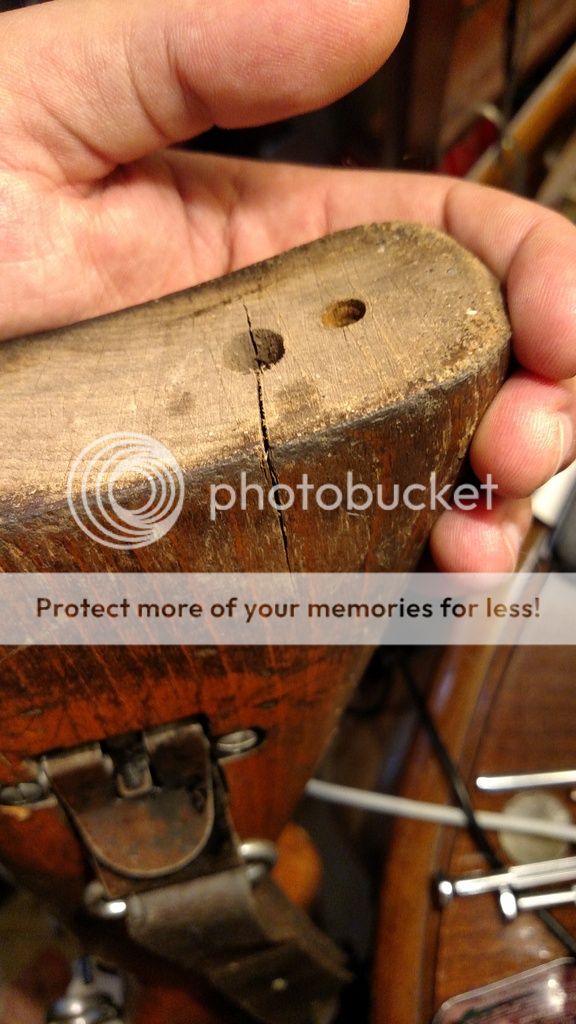

Hello everybody, I recently picked up a K31 and wanted to get some opinions on what I should do with some of its issues. As you can see from the pics below, the buttstock has some pretty big cracks and the wood in general is pretty rough. My biggest concern with the cracks is that the top crack through the buttplate screw hole is big enough that the screw will not tighten.

So how should I go about cleaning up the stock? I'm pretty good with mechanical repairs but I have little woodworking experience. Which brings me to my second question, am I better off finding a gunsmith to repair the cracks and cleaning up the wood? I'm always up for a project but I would like to not get in over my head. Finally if I do go ahead and repair the cracks, should I use acraglas, nice wood glue, or epoxy? All opinions/advice welcome.

I can also post more pics if anyone is interested. I bought this gun as a shooter so the bluing is worn in some spots but its all matching and has a clean bore.

So how should I go about cleaning up the stock? I'm pretty good with mechanical repairs but I have little woodworking experience. Which brings me to my second question, am I better off finding a gunsmith to repair the cracks and cleaning up the wood? I'm always up for a project but I would like to not get in over my head. Finally if I do go ahead and repair the cracks, should I use acraglas, nice wood glue, or epoxy? All opinions/advice welcome.

I can also post more pics if anyone is interested. I bought this gun as a shooter so the bluing is worn in some spots but its all matching and has a clean bore.

.

.