Doco Overboard

Ultimate Member

Ok, now were going to make something happen. Clean and inspect your threads. Dry them with carb cleaner or some other sort of solvent that quickly dries. The barrel should screw in easily by hand and not get hung or grab excessively. Were going to install without grease or lube, that's because of the square threads.

Make sure you have enough crush once tightened. Theirs table top methods for peening or rolling the barrel shoulder if the right amount of torque cannot be achieved or if the barrel will over index. We don't have to get into that here because we have a pretty good fitting barrel. The barrel is a High Standard rebuild barrel which are known for quality and accuracy. HS made the Smith Corona barrels for the 03A3.

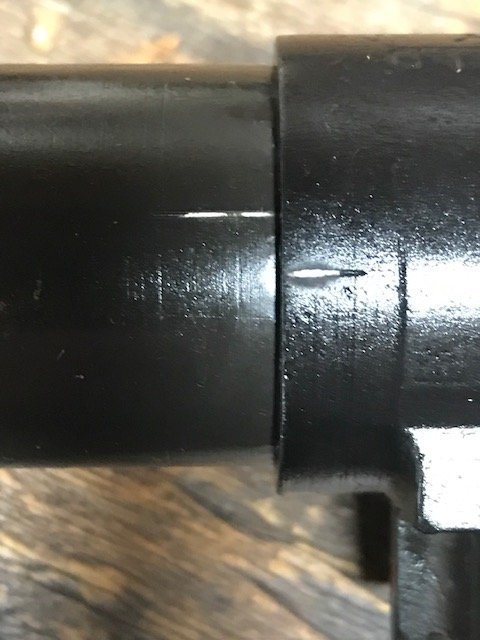

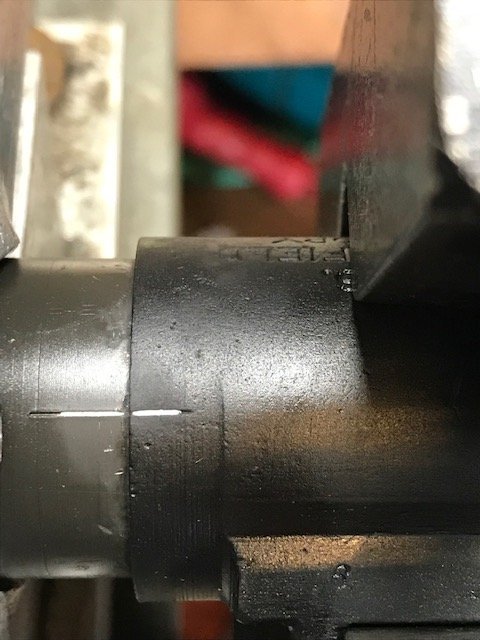

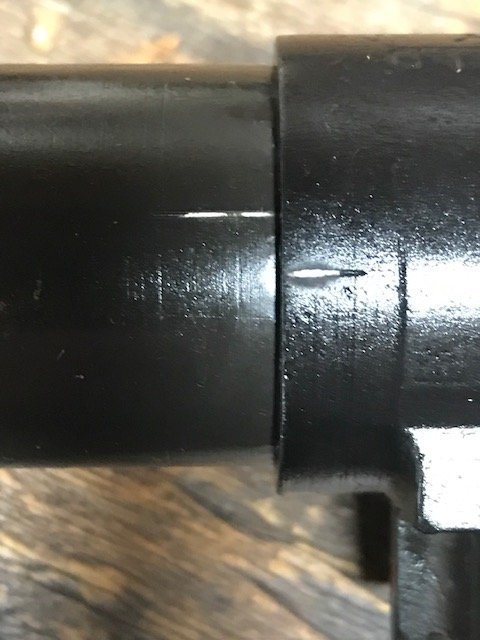

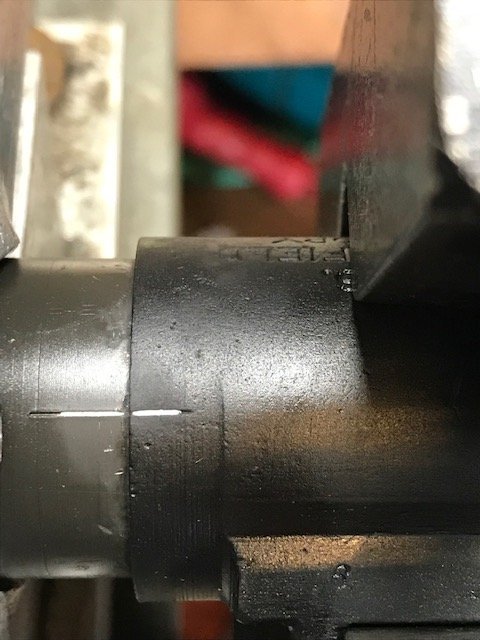

Chuck that sucker up in your rigging, just like we did when we freed the old one. That wrench pointing slightly downward will give good leverage as you pull upwards and allow you to see the index marks as they meet. Use your legs with your arms locked tight not your back or arms.

Give it a good smooth even steady pull. looks pretty good so far.....

Even better! No sense in rushing. Take the time to look things over and make sure it's right. Some barrels on different US rifles will all be a little different regarding crush and initial index. The 03A3 barrels often have a little more initial index which means you will sometimes have to run the barrel up and down to tight to get the right amount of bump needed to index them. Just go slow and smooth to prevent heat and galling or try to perform a miracle.

Every once in a while you may have to skim a little off the barrel shoulder. M17's are usually close to the mark but seem to tighten more rapidly. The diameter of the barrel stub is larger as well. Garands can be anywhere in between but are usually close to index and need rolling out or peening for a take off barrel.

You never know what your going to get.

Strip your bolt entirely make sure the chambers clean and dry and get your gauges. I marked them 1 2 3 in the next picture if you can see them so you can get an approximate idea of how far the bolt will rotate towards battery. Use a light touch and don't force the hardened gauge in to the chamber! Let gravity do its thing.

Here is the go gauge No 1 which will indicate the bolt will close and the chamber is to full depth. The chamber and bolt combination are within minimum chamber dimension but will still accept a cartridge to the maximum dimension without causing excessive pressure.

The bolt handle should fall with a little tink as it hits the receiver.

No 2 the No Go proves the chamber is not longer than spec established by the longest cartridge dimension that would normally be encountered with factory ammunition. The no go is an intermediate gauge that demonstrates the chamber adequately supports the brass case allowing it to be fired without excessive stretching. A chamber that closes on a no go does not mean its unsafe, just that there is enough tolerance to be at or near the max dimension.

The field gauge, is used when the chamber doesn't pass the no go gauge (the bolt closes) to ensure that the chamber is within the realm of safety regarding the cartridge cases ability to resist separating upon firing.

Wait..... theirs another one! The one that matters because my rifles don't shoot no stinking gauges.

See next post for more.

Make sure you have enough crush once tightened. Theirs table top methods for peening or rolling the barrel shoulder if the right amount of torque cannot be achieved or if the barrel will over index. We don't have to get into that here because we have a pretty good fitting barrel. The barrel is a High Standard rebuild barrel which are known for quality and accuracy. HS made the Smith Corona barrels for the 03A3.

Chuck that sucker up in your rigging, just like we did when we freed the old one. That wrench pointing slightly downward will give good leverage as you pull upwards and allow you to see the index marks as they meet. Use your legs with your arms locked tight not your back or arms.

Give it a good smooth even steady pull. looks pretty good so far.....

Even better! No sense in rushing. Take the time to look things over and make sure it's right. Some barrels on different US rifles will all be a little different regarding crush and initial index. The 03A3 barrels often have a little more initial index which means you will sometimes have to run the barrel up and down to tight to get the right amount of bump needed to index them. Just go slow and smooth to prevent heat and galling or try to perform a miracle.

Every once in a while you may have to skim a little off the barrel shoulder. M17's are usually close to the mark but seem to tighten more rapidly. The diameter of the barrel stub is larger as well. Garands can be anywhere in between but are usually close to index and need rolling out or peening for a take off barrel.

You never know what your going to get.

Strip your bolt entirely make sure the chambers clean and dry and get your gauges. I marked them 1 2 3 in the next picture if you can see them so you can get an approximate idea of how far the bolt will rotate towards battery. Use a light touch and don't force the hardened gauge in to the chamber! Let gravity do its thing.

Here is the go gauge No 1 which will indicate the bolt will close and the chamber is to full depth. The chamber and bolt combination are within minimum chamber dimension but will still accept a cartridge to the maximum dimension without causing excessive pressure.

The bolt handle should fall with a little tink as it hits the receiver.

No 2 the No Go proves the chamber is not longer than spec established by the longest cartridge dimension that would normally be encountered with factory ammunition. The no go is an intermediate gauge that demonstrates the chamber adequately supports the brass case allowing it to be fired without excessive stretching. A chamber that closes on a no go does not mean its unsafe, just that there is enough tolerance to be at or near the max dimension.

The field gauge, is used when the chamber doesn't pass the no go gauge (the bolt closes) to ensure that the chamber is within the realm of safety regarding the cartridge cases ability to resist separating upon firing.

Wait..... theirs another one! The one that matters because my rifles don't shoot no stinking gauges.

See next post for more.

I can't imagine a boot doing 96 count manual of arms with a plastic pos doing anything for the bicep!

I can't imagine a boot doing 96 count manual of arms with a plastic pos doing anything for the bicep!

use some sort of epoxy or plastic to hide the bodge.

use some sort of epoxy or plastic to hide the bodge.