alucard0822

For great Justice

I sort and tumble clean brass after I collect enough from the range.

Put a few handfuls of brass in a cardboard box, spray some lube, shake it, dump in my case feeder.

Run through progressive to decap, size, at least 1K rounds an hour.

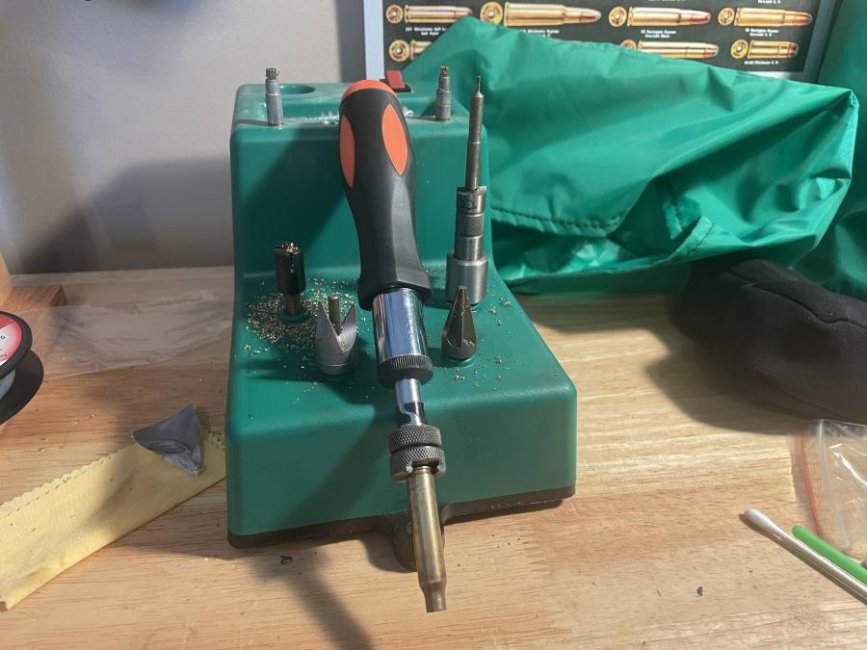

Use the Frankfort case prep center to trim, chamfer, deburr, and flip to ream crimped primer pockets, toss in the tumbler to final clean and get lube off. Probably 500 cases an hour.

Run through the press, decap in position 1 cleans media out of the primer hole/pocket. Then prime, charge, place a bullet, seat, crimp, and it's done. 500 rounds an hour.

Start to finish I can do a thousand rounds from my bin of clean brass to completed ammo in about 5 hours of work, usually split it up by operation over a few nights. Trimming sucks worst, manual trimmers are torture, using a case holder in a drill is a little faster; but the Frankford prep center or possum hollow goes well enough. Would like a press mounted trimmer to get that done after sizing, and basically save an hour or more per K, but really only comes in handy with large runs, and I can live with what I got for only a few thousand a year.

Put a few handfuls of brass in a cardboard box, spray some lube, shake it, dump in my case feeder.

Run through progressive to decap, size, at least 1K rounds an hour.

Use the Frankfort case prep center to trim, chamfer, deburr, and flip to ream crimped primer pockets, toss in the tumbler to final clean and get lube off. Probably 500 cases an hour.

Run through the press, decap in position 1 cleans media out of the primer hole/pocket. Then prime, charge, place a bullet, seat, crimp, and it's done. 500 rounds an hour.

Start to finish I can do a thousand rounds from my bin of clean brass to completed ammo in about 5 hours of work, usually split it up by operation over a few nights. Trimming sucks worst, manual trimmers are torture, using a case holder in a drill is a little faster; but the Frankford prep center or possum hollow goes well enough. Would like a press mounted trimmer to get that done after sizing, and basically save an hour or more per K, but really only comes in handy with large runs, and I can live with what I got for only a few thousand a year.