Since you saw it here ( https://www.mdshooters.com/showpost.php?p=4867847&postcount=1 ) first, I guess I should do a build thread on it.

This is how I put together a 1919 in a few days. Sorry I don't have more pictures because I wasn't expecting to do a thread on it.

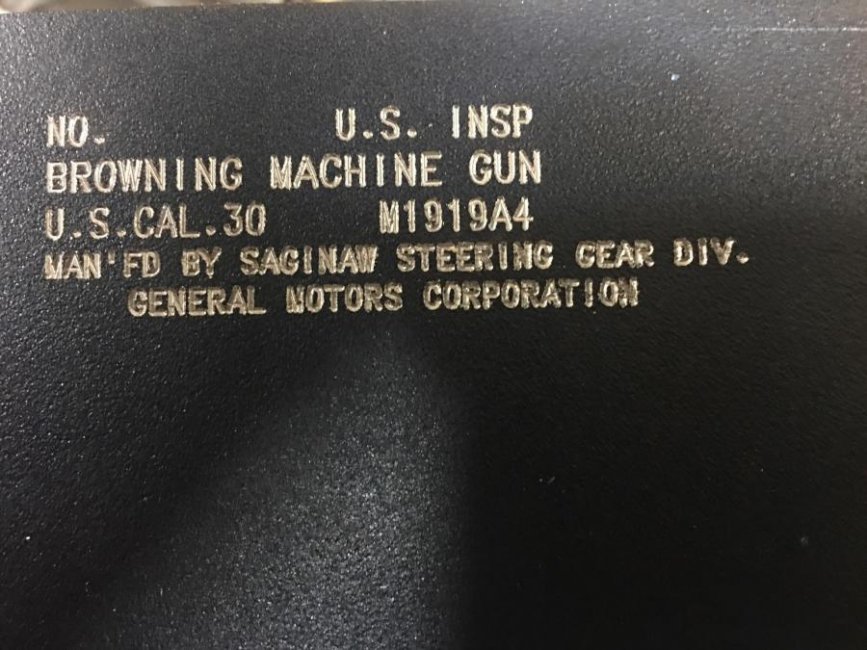

First is to find a kit. I took advantage of the temporary Cetme-L availability issues and sold a bunch of extra stuff to get the 1919 kit very cheap. Expect to pay $1500 or more if you can't find a deal. My kit was an Israeli lend lease kit and as such had most of the necessary conversion parts for 7.62Nato. I found an Israeli drilled tripod for $200, 1K Israeli links for $75 and also found some NOS 100 RND USGI surplus belts that had buckles added to them for pack straps. They are 99 rnd now, but I couldn't beat the price for $12 each shipped. Will order some repo starter tabs from sarco and try to find someone local with a belt loading machine to stretch them for the first loading.

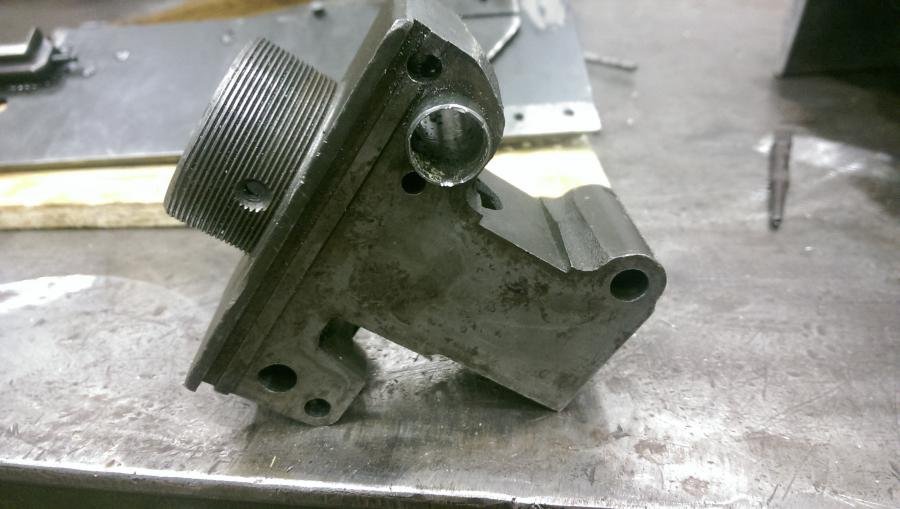

My kit still had the trunion attached to the left side plate, so I had some demil to do before building. Whomever started the demil probably worked for Century because it was rough. The barrel shroud is original USGI and still had the 30-06 booster on it.

The last picture is before I started working on it. Just put the parts on the tripod when everything came in.

Here is a great tutorial from 1919a4.com http://1919a4.com/showthread.php?421-Build-Sequence-Checklist

This is how I put together a 1919 in a few days. Sorry I don't have more pictures because I wasn't expecting to do a thread on it.

First is to find a kit. I took advantage of the temporary Cetme-L availability issues and sold a bunch of extra stuff to get the 1919 kit very cheap. Expect to pay $1500 or more if you can't find a deal. My kit was an Israeli lend lease kit and as such had most of the necessary conversion parts for 7.62Nato. I found an Israeli drilled tripod for $200, 1K Israeli links for $75 and also found some NOS 100 RND USGI surplus belts that had buckles added to them for pack straps. They are 99 rnd now, but I couldn't beat the price for $12 each shipped. Will order some repo starter tabs from sarco and try to find someone local with a belt loading machine to stretch them for the first loading.

My kit still had the trunion attached to the left side plate, so I had some demil to do before building. Whomever started the demil probably worked for Century because it was rough. The barrel shroud is original USGI and still had the 30-06 booster on it.

The last picture is before I started working on it. Just put the parts on the tripod when everything came in.

Here is a great tutorial from 1919a4.com http://1919a4.com/showthread.php?421-Build-Sequence-Checklist

Attachments

Last edited: