OrbitalEllipses

Ultimate Member

Buy a case of PRIME 130gr to shoot for the class. Then reload those sweet Norma brass cases forever.

Last edited:

Thanks for the info. Didn't even consider the Forester dies.All presses do the same thing to one degree or another. The real ticket is the dies.

I run forster dies for my 6.5, and they're great. The Full length barely *BARELY* bumps the neck and body back to chamber dimensions, and I seat with a forster micrometer die.

Forster dies are a little less expensive than reddings, and I honestly feel the quality is higher than the reddings.

I know that seems like blasphemy to some, but its my personal opinion. I dont like getting gouged extra for minor features that come stock on other brands of dies for marginally less cost.

You in theory would be best served by a Forster neck die, forster micrometer seating die, and a lee body size die (for when the cartridge gets hard to chamber)

Buy a case of 130gr to shoot for the class. Then reload those sweet Norma brass cases forever.

Forgive my ignorance, is the Norma brass that much better than Hornady brass?

I mean, I have like ~120 Hornady cases if you want to buy them to figure out if they're any good.

120 6.5 Hornady brass? How much you want? If he doesn't take them, I'd be interested.

Found some H4350 at Clyde's today. It was their last one.

They also had a bunch of CCI and Winchester primers in stock, not the bench rest or match though.

Now if I can find some 140 gr ELD-M bullets.

If you need some 140gr eldm, I can spare a few and maybe some cci BR primers

H4350 powder for sure..start 2 thousands off the lands. Find out max load and subtract 10% as a starting point. Go up 1% increments, load 3 rounds for each and shoot groups at 100 yards.

You will likely have 2 accuracy nodes, one on the low powder side and one closer to max.

Look at the next charge weight above and below, and make sure they hit close to the same point if impact. Theory is if you over/under throw a powder charge by 1% you will still hit same POI.

Once you dial in the powder charge, do the same test with seating depth.

Bumping this for some assistance and quoting a post from another thread.

Ok I ended up buying two lbs of AA4350 to reload 6.5CM. There is no load data on Accurate's website for this powder in 6.5CM. After a ton of searching I was able to find only a few references to loads of AA4350 on Snipers Hide forums. There was only post with loads using 140gr projectiles and 24" barrel, Hornady Brass and CCI primers at 42gr. A second post where a member had contacted Accurate and they recommended 43.5gr max load 103% compacted. I didn't want to use this outright so I did find load data from Hornady for 120gr Amax as well as Accurate listed data for 260 Remington with 140gr Amax. After comparing all of these references in a data table, I decided it would be safe to test loads from 39.2 to 42.8.

Today was my first chance to test 3 rounds of each load and I'm a bit puzzled by the results.

1) all 10 groups were pretty tight 7/10 were 0.6moa or better and the two best groups were .42 and .46 I was expecting more of a spread, is this uncommon? Should I expect the accuracy nodes to be better than .42moa?

2) the max load of 42.8 gr had a Mv of 2659 fps I was expecting closer to 2800 fps. The cases show no signs of over pressure and and I'm still about 0.7 gr from the unposted max, I'm wondering if it makes sense to test further. Could I expect any reasonable improvement.

3) today was cold. does the lower temperature have and noticeable impact on velocity?

Sent from my iPad using Tapatalk

IMR-4350 burns slightly faster in the 6.5CM/.260 class cartridges. This means you will reach your OCW and maximum charge weight sooner, and at lower velocity.Going by E.Shell's word, not EXACTLY similar.

I haven't loaded with IMR4350, but I can say that I have yet to find as stable a load as I have with H4350.

Agreed 100%. And H-4350 is probably what you'll be happiest with. Micrometer dies are not necessarily more precise and their main utility is to return to a given setting, which doesn't matter to most shooters, myself included.I use a set of Redding dies. A micrometer seating die is nice for developing a load, but once that is done the die will be set anyway. You can still adjust a regular seating die, it just takes a little more tuning. As far as a load, find (and look hard) H4350 and a good 140ish grain bullet. Somewhere in the area of 42-43 grains of powder and you will do just fine. My load is 43.1 with a hornady 140 bthp. Speed is right at 2815.

I'd agree, and wish I had realized this before dumping extra money into fancy dies when a standard set of decent dies will work.Any good brand of dies that you are used to using will work fine. I've loaded quite a bit of precision rifle ammo.

I'd love to tell you my expensive Redding Dies load way better ammo than my cheap Lee dies, but I really can't demonstrate it. (and my standards are pretty high)

The Redding dies are a little easier and "nicer" to work with, but as mentioned above, once they are set up it matters little. Not saying you shouldn't get the ones you want, just that the consistency of your reloading technique matters more that how fancy your equipment is. I have Lee and Redding presses and dies, and use a mix of them. I can load ammo good enough to win any practical/ tactical long range match with my Lee Turret press and dies.

IMHO, this is the very best approach. If neck sizing solves some kind of problem for you, your full length sizing technique is wrong.I full length size every time, just enough that they chamber with no resistance.

Forster dies are good dies, and setting the full length sizer to barely bump the shoulder is the way that produces best results in several ways.All presses do the same thing to one degree or another. The real ticket is the dies.

I run forster dies for my 6.5, and they're great. The Full length barely *BARELY* bumps the neck and body back to chamber dimensions, and I seat with a forster micrometer die.

Forster dies are a little less expensive than reddings, and I honestly feel the quality is higher than the reddings.

I know that seems like blasphemy to some, but its my personal opinion. I dont like getting gouged extra for minor features that come stock on other brands of dies for marginally less cost.

You in theory would be best served by a Forster neck die, forster micrometer seating die, and a lee body size die (for when the cartridge gets hard to chamber)

Go with the CCIs first. I think the Winchesters are a little hot (increased brisance) to produce consistent loads in this capacity case....They also had a bunch of CCI and Winchester primers in stock, not the bench rest or match though...

Research "OCW" and don't worry so much about absolute precision (as defined by statistically insignificant 3 and 5 shot group samples). Group sizes are too easily influenced by too many factors, plus, you will often find the results you mention below that initially seem perplexing.Bumping this for some assistance and quoting a post from another thread.

Ok I ended up buying two lbs of AA4350 to reload 6.5CM. There is no load data on Accurate's website for this powder in 6.5CM. After a ton of searching I was able to find only a few references to loads of AA4350 on Snipers Hide forums. There was only post with loads using 140gr projectiles and 24" barrel, Hornady Brass and CCI primers at 42gr. A second post where a member had contacted Accurate and they recommended 43.5gr max load 103% compacted. I didn't want to use this outright so I did find load data from Hornady for 120gr Amax as well as Accurate listed data for 260 Remington with 140gr Amax. After comparing all of these references in a data table, I decided it would be safe to test loads from 39.2 to 42.8.

A good rifle will shoot almost any reasonable load well. It is typical to find very little differences in absolute group sizes and these differences are often due to the shooter and/or environmental parameters. Once we have established that the rifle is shooting several loads in a series with a given set of components with acceptable accuracy, we need to look for stable velocity in order to be successful at the longer distances this cartridge was designed for.Today was my first chance to test 3 rounds of each load and I'm a bit puzzled by the results.

1) all 10 groups were pretty tight 7/10 were 0.6moa or better and the two best groups were .42 and .46 I was expecting more of a spread, is this uncommon? Should I expect the accuracy nodes to be better than .42moa?

It definitely does pay to pursue testing to the point where you see signs of pressure.2) the max load of 42.8 gr had a Mv of 2659 fps I was expecting closer to 2800 fps. The cases show no signs of over pressure and and I'm still about 0.7 gr from the unposted max, I'm wondering if it makes sense to test further. Could I expect any reasonable improvement.

Yes, it can. This is why many long range shooters have gravitated toward Hodgden's 'extreme' powders. I have found IMR powders to be quite sensitive to temperature changes and don't use them for long range.3) today was cold. does the lower temperature have and noticeable impact on velocity?

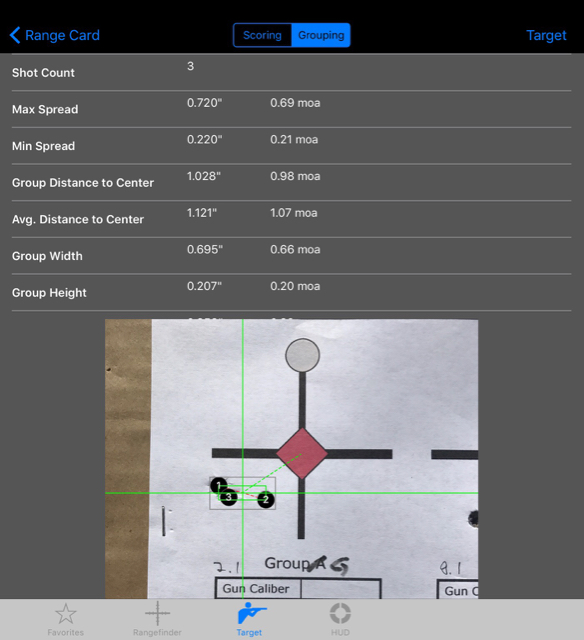

Both groups indicate rifle handling or trigger issues, but both show potential and I would personally work more toward finding stable velocity and working with that.Here are the two best groups.

[snip]//uploads.tapatalk-cdn.com/20170313/4ae5d809ae28eef6738e6ef06f9402c8.jpg[/IMG]

[snip]//uploads.tapatalk-cdn.com/20170313/3dd00503f53c8216c3d8ce48aab5a1f8.jpg[/IMG]

No, in fact, best loads usually run toward higher, but still safe, pressures.Is there any advantage if choosing the slower/lower pressure group over the higher velocity group?

You may not realize that this inane advertisement for Tapatalk can be eliminated by a simple setting.Sent from my iPad using Tapatalk

How far apart were the charge weights?

Don't worry about speed/FPS as much as accuracy, you can dial for elevation as long as they hit at the same spot.

Most of the time, as in non-benchrest quality rifles, neck sizing works against pure precision, despite "intuition" and "feelings" to the contrary. In most production guns, a very tight fit to the chamber, the very goal of neck sizing, forces bullet misalignment in the throat and CREATES issues.

It is typical to find very little differences in absolute group sizes and these differences are often due to the shooter and/or environmental parameters.

Further, most consistent performance is often found at just below maximum charge weights. Again, research OCW, and you may also find this helpful:

http://www.shell-central.com/Powder1.html

Don't get hung up on absolute velocity, as Speed3 stated above, it amounts to a click or three one way or another. For long range precision, the goal should be consistent velocities, wherever they may live.

IMR-4350 burns slightly faster in the 6.5CM/.260 class cartridges. This means you will reach your OCW and maximum charge weight sooner, and at lower velocity.

You may not realize that this inane advertisement for Tapatalk can be eliminated by a simple setting.

DEF read and re read anything that comes out of Ed's mouth. To be honest F all the other stuff you read all over the internet and follow his advice. He is a HELL of a resource

Welcome to the dark side...OK, Mind Blown! I'll take your word. Time to read more and put away the neck sizing die.

This is where it pays to understand that some data may not tell us the story we are looking for.....All factors which could cause inconsistencies. In fact in retrospect probably not a good day to be testing.

Just checked out the link for a second and realize I'll be dedicating the rest of the evening to reading your link and the referenced sub-links. Thank You!

Yes, "0" would be optimum. The real test is the size of your vertical deviation when you put it into context of your rifle and the ranges you are shooting.]This part is a bit new to me. I just got my first Chronograph. The 5 Factory A-Max 120gr loads I shot before testing my loads were running Mv:2868 with an SD: 13.6. For my test loads my SD ranged from 9 to 44. What should I be looking for with respect to Standard Deviation? Is the answer simply as close to 0 as possible...

H-4350 wasn't hard to find until everybody discovered it was optimum for the 6.5 Creedmoor.It seems that H4350 is very difficult to find, so my concern was working up a load with a powder that was not going to be available when I needed it.

I'd be very interested to see your ultimate findings with the AA version.I read some of the same info you mentioned about IMR4350 being a bit faster which I why I wanted to try AA4350 which is actually lower than H4350. At this point I'm going to continue testing if for nothing else but to at least to give back some data to the community. If the powder can perform at consistent velocity it may be a keeper.