toolness1

Ultimate Member

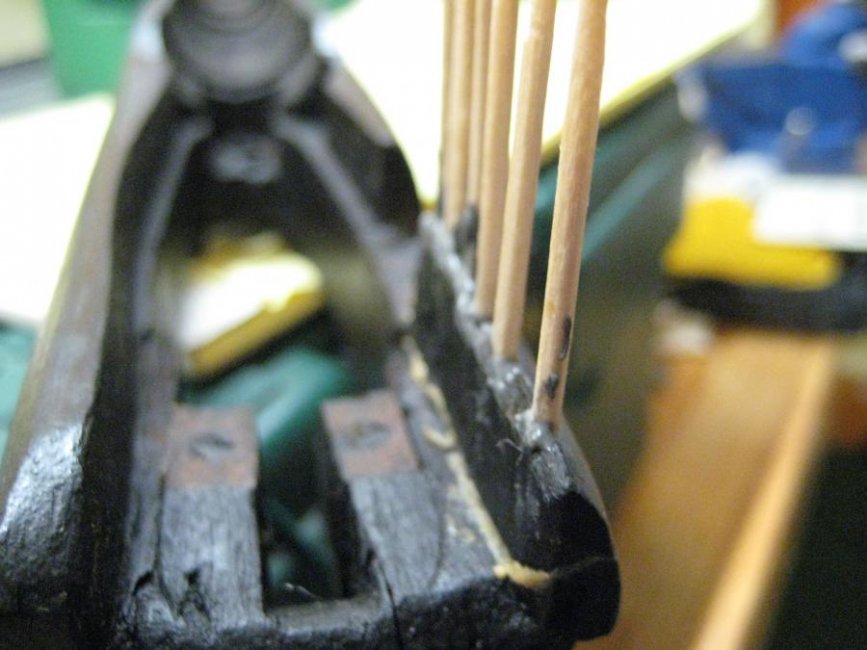

I was shooting my No.1 Mk III a few weeks ago and this chunk broke off the stock.

I tried degreasing the wood and using JB Weld wood glue, but it broke off after a few shots.

I am guessing I'm gonna have to use some brass rod or wood dowels, but I am new to stock repair and don't know the best way to go about doing so.

I am not sure what the best way is to make the holes for the brass screw/rod or wood dowel.

The top of this piece is angled, so drilling is going to be pretty tricky.

I would love some suggestions on how to fix this.

I searched around on the net and found a picture of another stock where there were two brass screws or pins holding an identical crack in place, but I don't know how the heck they did it.

The only idea I had was to put the piece in place, and drill down through it and into the stock with a very small drill bit, then use bits of increasing size to get the holes big enough for the brass rod or screw, or wood dowel.

I think if I use a small enough bit, I could get a bite in it even at that angle, but it wouldn't be easy.

I do have a drill press so I can probably clamp the rifle in place and hold that broken chunk in place while I drill it.

Thanks for any help!

I tried degreasing the wood and using JB Weld wood glue, but it broke off after a few shots.

I am guessing I'm gonna have to use some brass rod or wood dowels, but I am new to stock repair and don't know the best way to go about doing so.

I am not sure what the best way is to make the holes for the brass screw/rod or wood dowel.

The top of this piece is angled, so drilling is going to be pretty tricky.

I would love some suggestions on how to fix this.

I searched around on the net and found a picture of another stock where there were two brass screws or pins holding an identical crack in place, but I don't know how the heck they did it.

The only idea I had was to put the piece in place, and drill down through it and into the stock with a very small drill bit, then use bits of increasing size to get the holes big enough for the brass rod or screw, or wood dowel.

I think if I use a small enough bit, I could get a bite in it even at that angle, but it wouldn't be easy.

I do have a drill press so I can probably clamp the rifle in place and hold that broken chunk in place while I drill it.

Thanks for any help!