I had a few parts laying around and finally decided to do something with them, in this picture you can see the lowly Avis 03 barrel

In the next series I prepped the barrel by removing the rear sight base, which didn't go so well so I had to break out the secret piece of chain-link fence rail to get it off. ( that just happens to fit the rear of the collar when the barrel is removed. This one was a few degrees off index) And then do a little chamber scrubbing

In the next series I prepped the barrel by removing the rear sight base, which didn't go so well so I had to break out the secret piece of chain-link fence rail to get it off. ( that just happens to fit the rear of the collar when the barrel is removed. This one was a few degrees off index) And then do a little chamber scrubbing

inspect the crown and then touch up Mr frosty[/ATTACH] do a little maintenance

inspect the crown and then touch up Mr frosty[/ATTACH] do a little maintenance

to old faithful and then hand tighten the barrel and action together to see how close the witness marks were apart which happened to be a little close so peening the barrel shoulder lightly was in order to get a touch more than a 1/4" draw[/ATTACH] You can do this on a one time basis and luckily my donor was not already beat to hell.

to old faithful and then hand tighten the barrel and action together to see how close the witness marks were apart which happened to be a little close so peening the barrel shoulder lightly was in order to get a touch more than a 1/4" draw[/ATTACH] You can do this on a one time basis and luckily my donor was not already beat to hell.

Make the marks meet to about 40-60 ft. lbs of torque and then grab the fistful of bolts to find a winner for the already chambered barrel.

Make the marks meet to about 40-60 ft. lbs of torque and then grab the fistful of bolts to find a winner for the already chambered barrel.

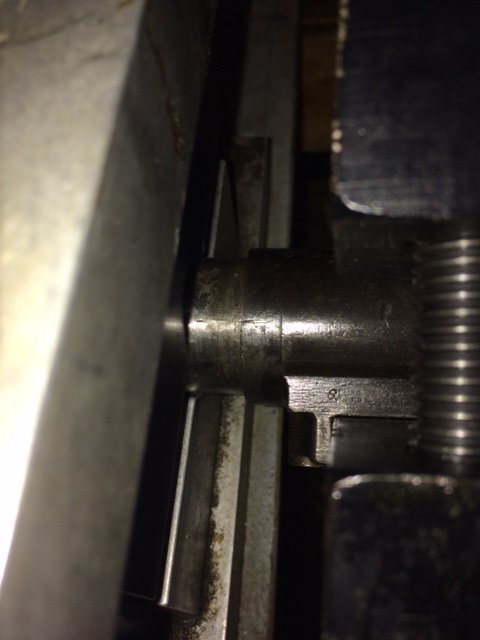

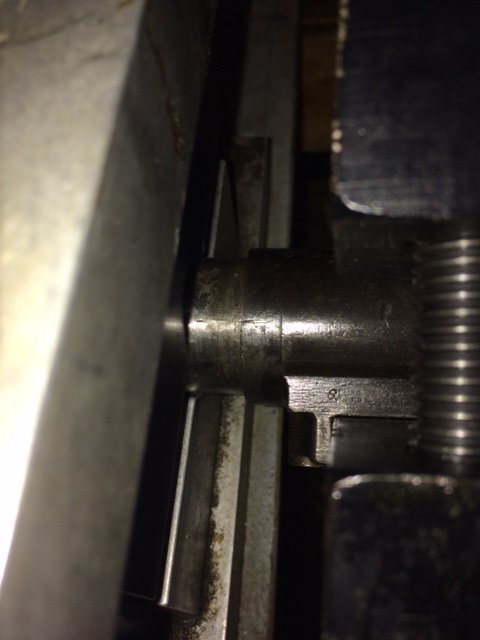

I got lucky and had a number of bolts that were suitable not closing on the no go gauge but settled on a BF 42 03 replacement that was new old stock. Interestingly there were a couple of early SHT bolts that would and would not close and one that you could just feel slight resistance when it was almost home. Once all that was done I re-assembled the barreled action and function tested with some dummy cartridges filled with sand for extra weight. The last picture is of the dreadful coned breech that generates alot of discussion but you can see that the front of the extractor slot is right at the end of the breech in the extractor cut, wich is the thickest part of a case. There was a little radial play with the resized dummies but not enough to get all tore up about. Thanks to Stripper clip on the CMP forum who was kind enough to provide the barrel with both sight bases attached for a song. The only thing left is to marry the conglomeration up with a nice scant stock to ring old crusty out and lap the muzzle with my cordless drill that was not returned by number one son who is nowhere to be found with my stuff..... whoops 10 files, see coned breech on next one.

I got lucky and had a number of bolts that were suitable not closing on the no go gauge but settled on a BF 42 03 replacement that was new old stock. Interestingly there were a couple of early SHT bolts that would and would not close and one that you could just feel slight resistance when it was almost home. Once all that was done I re-assembled the barreled action and function tested with some dummy cartridges filled with sand for extra weight. The last picture is of the dreadful coned breech that generates alot of discussion but you can see that the front of the extractor slot is right at the end of the breech in the extractor cut, wich is the thickest part of a case. There was a little radial play with the resized dummies but not enough to get all tore up about. Thanks to Stripper clip on the CMP forum who was kind enough to provide the barrel with both sight bases attached for a song. The only thing left is to marry the conglomeration up with a nice scant stock to ring old crusty out and lap the muzzle with my cordless drill that was not returned by number one son who is nowhere to be found with my stuff..... whoops 10 files, see coned breech on next one.

In the next series I prepped the barrel by removing the rear sight base, which didn't go so well so I had to break out the secret piece of chain-link fence rail to get it off. ( that just happens to fit the rear of the collar when the barrel is removed. This one was a few degrees off index) And then do a little chamber scrubbing

In the next series I prepped the barrel by removing the rear sight base, which didn't go so well so I had to break out the secret piece of chain-link fence rail to get it off. ( that just happens to fit the rear of the collar when the barrel is removed. This one was a few degrees off index) And then do a little chamber scrubbing

inspect the crown and then touch up Mr frosty[/ATTACH] do a little maintenance

inspect the crown and then touch up Mr frosty[/ATTACH] do a little maintenance

to old faithful and then hand tighten the barrel and action together to see how close the witness marks were apart which happened to be a little close so peening the barrel shoulder lightly was in order to get a touch more than a 1/4" draw[/ATTACH] You can do this on a one time basis and luckily my donor was not already beat to hell.

to old faithful and then hand tighten the barrel and action together to see how close the witness marks were apart which happened to be a little close so peening the barrel shoulder lightly was in order to get a touch more than a 1/4" draw[/ATTACH] You can do this on a one time basis and luckily my donor was not already beat to hell.

Make the marks meet to about 40-60 ft. lbs of torque and then grab the fistful of bolts to find a winner for the already chambered barrel.

Make the marks meet to about 40-60 ft. lbs of torque and then grab the fistful of bolts to find a winner for the already chambered barrel.

I got lucky and had a number of bolts that were suitable not closing on the no go gauge but settled on a BF 42 03 replacement that was new old stock. Interestingly there were a couple of early SHT bolts that would and would not close and one that you could just feel slight resistance when it was almost home. Once all that was done I re-assembled the barreled action and function tested with some dummy cartridges filled with sand for extra weight. The last picture is of the dreadful coned breech that generates alot of discussion but you can see that the front of the extractor slot is right at the end of the breech in the extractor cut, wich is the thickest part of a case. There was a little radial play with the resized dummies but not enough to get all tore up about. Thanks to Stripper clip on the CMP forum who was kind enough to provide the barrel with both sight bases attached for a song. The only thing left is to marry the conglomeration up with a nice scant stock to ring old crusty out and lap the muzzle with my cordless drill that was not returned by number one son who is nowhere to be found with my stuff..... whoops 10 files, see coned breech on next one.

I got lucky and had a number of bolts that were suitable not closing on the no go gauge but settled on a BF 42 03 replacement that was new old stock. Interestingly there were a couple of early SHT bolts that would and would not close and one that you could just feel slight resistance when it was almost home. Once all that was done I re-assembled the barreled action and function tested with some dummy cartridges filled with sand for extra weight. The last picture is of the dreadful coned breech that generates alot of discussion but you can see that the front of the extractor slot is right at the end of the breech in the extractor cut, wich is the thickest part of a case. There was a little radial play with the resized dummies but not enough to get all tore up about. Thanks to Stripper clip on the CMP forum who was kind enough to provide the barrel with both sight bases attached for a song. The only thing left is to marry the conglomeration up with a nice scant stock to ring old crusty out and lap the muzzle with my cordless drill that was not returned by number one son who is nowhere to be found with my stuff..... whoops 10 files, see coned breech on next one.

![InkedIMG_1143[861]_LI.jpg InkedIMG_1143[861]_LI.jpg](https://www.mdshooters.com/data/attachments/178/178367-fba0cba91d5f0e1036671986f17c8c73.jpg)