Combloc

Stop Negassing me!!!!!

I wanted one of these pistols and one of the P64's when they were imported several years ago but I didn't get either one because I just couldn't get past the awful import stamp on their slides. Then they disappeared and I wished I had bought them. I have a Polish AKM built from a matching parts kit, a Polish RPD built from a matching parts kit and a MAG98 pistol, but I didn't have a P64 or a P83 because of that stupid import stamp.

Well, both came around again and I picked both up. The P64, as you all know, is a typical Warsaw Pact blowback pistol chambered in 9x18 Makarov made the same way they all used to be; that is to say milled from solid stock. Neat and fun but, lets face it, nothing much in the innovation department. At first glance, theP83 is more of the same. It's a simple Warsaw Pact blowback built in the quadrillions to arm the proletariat armies in the defense of the motherland against the impending Capitalist hoards. From a functional design standpoint, that is true. The trigger pull is long, creepy and heavy. The safety lever is tiny and hard to manipulate. The hammer is huge and lacks ergonomics. The safety dot paint looks like a three year old did it with his eyes closed on a bus with poor suspension an a cobblestone street. The sights are tiny and the finish is rough compared to even other Eastern Bloc offerings. But it's dead reliable and that's what really counts in the end.

There is nothing special and a lot copied in the P83. While it does have a couple interesting and original design details, the magazine and cartridge are pure Soviet PM. The takedown block is straight off the Sauer 38H and the trigger mechanism is an only slightly modified copy of that used in the Walther P38. The way the firing pin lowers when the safety is applied and the cutout in the hammer to accommodate this is also taken from Walther's P5. So there is nothing special about the design when seen in that light. I knew that and expected that. I also knew that the pistol was made primarily from stamped parts and that fact alone was what has intrigued me since I learned about it some years ago. Anybody who knows me or knows my work knows that I am absolutely fascinated by anything made of pressed metal, especially firearms. While the fact that the P83 is a stamped pistol is generally known, no real details about construction are available online so I knew I had to buy one to find out just how it was all put together. What I found so amazed me that I felt compelled to take some pictures to share with you all.

This little essay is not about how the P83 works or about documenting every part and mark, but rather about how it is built. When I took the slide and grips off of this thing to clean the storage cosmoline out of all the nooks and crannies, I was blown away by the sophistication and complexity exhibited in its construction. Although execution of the build and finish are crude by Western standards, the innovation hidden in this otherwise ordinary looking pistol is on par with it's grandfather, the Jager Pistole of 1914 and its contemporary, the HK P9S. If placing ANY Warsaw Pact pistol on the same level as an HK sounds wacko to you, trust me, I would laughed had you made the same statement to me just a couple days ago. I never expected to see such genius of manufacture embodied in a communist design; it just didn't seem possible......but it is. Let's get to some pictures and I'll show you what I mean.

This will take a few posts and I'm not doing them all at this moment. However, it should be done by tomorrow night so check back.

A Radom P83 made just before the fall of the iron curtain in 1989:

This particular pistol came from Widener's for the princely sum of $200 plus shipping. It has two matching magazines and a nicely worn in patina to it, just the way I like them. That means it helped make history instead of just passing through it. It also came with a cleaning rod but there isn't a picture of that because I only discovered it after I was finished with the camera. I'm not too bright.

Lets get a some comparison shots out of the way first. Here are couple pictures showing a size comparison between the P83, it's predecessor the P64 and an Izhevsk produced PM:

And here we see it compared to the worlds first use of pressed metal construction in a firearm, the Jager of 1914 and it's stamped contemporary, the HK P9S:

Here, the takedown block is lowered for disassembly. Below is an the Sauer 38H with its takedown block lowered for disassembly. Neato!

Let's look at the takedown block a little closer.

Up and ready for use:

The little hole in the trigger guard is for the ball detent in the takedown block to pop into and lock the block in place.

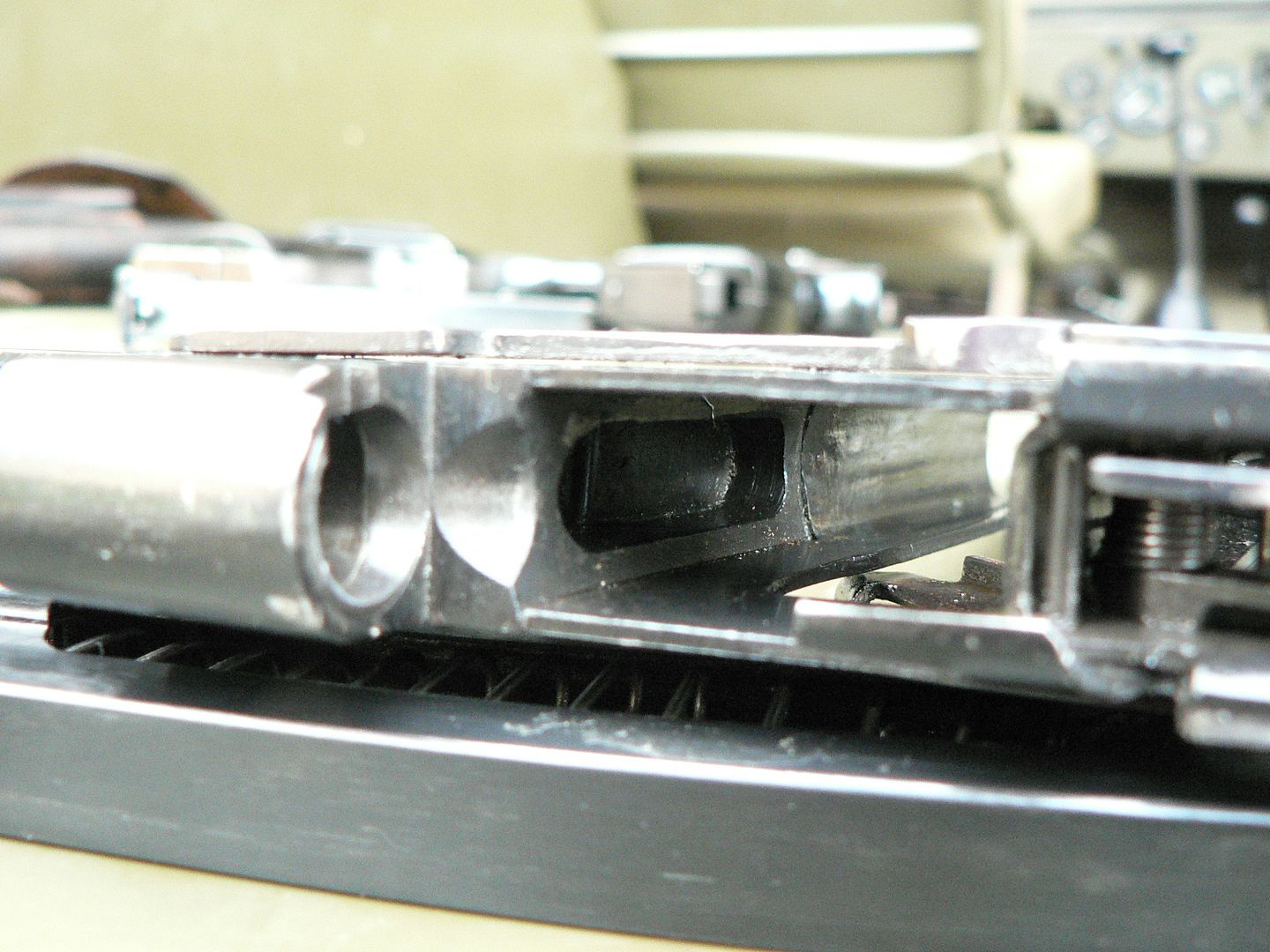

Down and ready for disassembly:

You can see the detent ball through the hole.

On the left is a P83 magazine and on the right is one from an East German produced Makarov:

Well, both came around again and I picked both up. The P64, as you all know, is a typical Warsaw Pact blowback pistol chambered in 9x18 Makarov made the same way they all used to be; that is to say milled from solid stock. Neat and fun but, lets face it, nothing much in the innovation department. At first glance, theP83 is more of the same. It's a simple Warsaw Pact blowback built in the quadrillions to arm the proletariat armies in the defense of the motherland against the impending Capitalist hoards. From a functional design standpoint, that is true. The trigger pull is long, creepy and heavy. The safety lever is tiny and hard to manipulate. The hammer is huge and lacks ergonomics. The safety dot paint looks like a three year old did it with his eyes closed on a bus with poor suspension an a cobblestone street. The sights are tiny and the finish is rough compared to even other Eastern Bloc offerings. But it's dead reliable and that's what really counts in the end.

There is nothing special and a lot copied in the P83. While it does have a couple interesting and original design details, the magazine and cartridge are pure Soviet PM. The takedown block is straight off the Sauer 38H and the trigger mechanism is an only slightly modified copy of that used in the Walther P38. The way the firing pin lowers when the safety is applied and the cutout in the hammer to accommodate this is also taken from Walther's P5. So there is nothing special about the design when seen in that light. I knew that and expected that. I also knew that the pistol was made primarily from stamped parts and that fact alone was what has intrigued me since I learned about it some years ago. Anybody who knows me or knows my work knows that I am absolutely fascinated by anything made of pressed metal, especially firearms. While the fact that the P83 is a stamped pistol is generally known, no real details about construction are available online so I knew I had to buy one to find out just how it was all put together. What I found so amazed me that I felt compelled to take some pictures to share with you all.

This little essay is not about how the P83 works or about documenting every part and mark, but rather about how it is built. When I took the slide and grips off of this thing to clean the storage cosmoline out of all the nooks and crannies, I was blown away by the sophistication and complexity exhibited in its construction. Although execution of the build and finish are crude by Western standards, the innovation hidden in this otherwise ordinary looking pistol is on par with it's grandfather, the Jager Pistole of 1914 and its contemporary, the HK P9S. If placing ANY Warsaw Pact pistol on the same level as an HK sounds wacko to you, trust me, I would laughed had you made the same statement to me just a couple days ago. I never expected to see such genius of manufacture embodied in a communist design; it just didn't seem possible......but it is. Let's get to some pictures and I'll show you what I mean.

This will take a few posts and I'm not doing them all at this moment. However, it should be done by tomorrow night so check back.

A Radom P83 made just before the fall of the iron curtain in 1989:

This particular pistol came from Widener's for the princely sum of $200 plus shipping. It has two matching magazines and a nicely worn in patina to it, just the way I like them. That means it helped make history instead of just passing through it. It also came with a cleaning rod but there isn't a picture of that because I only discovered it after I was finished with the camera. I'm not too bright.

Lets get a some comparison shots out of the way first. Here are couple pictures showing a size comparison between the P83, it's predecessor the P64 and an Izhevsk produced PM:

And here we see it compared to the worlds first use of pressed metal construction in a firearm, the Jager of 1914 and it's stamped contemporary, the HK P9S:

Here, the takedown block is lowered for disassembly. Below is an the Sauer 38H with its takedown block lowered for disassembly. Neato!

Let's look at the takedown block a little closer.

Up and ready for use:

The little hole in the trigger guard is for the ball detent in the takedown block to pop into and lock the block in place.

Down and ready for disassembly:

You can see the detent ball through the hole.

On the left is a P83 magazine and on the right is one from an East German produced Makarov:

Last edited: