kalister1

R.I.P.

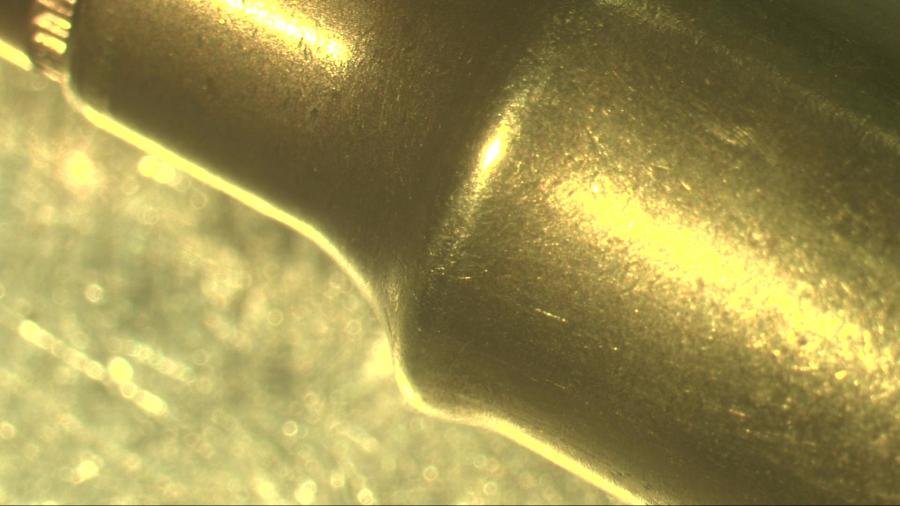

Has anybody seen this before?

I THINK that the case was too long before Lee Factory Crimp Die got it.

I use a (Worlds Finest Trimmer ?) which mounts in a drill press and uses the shoulder to reference from to get trim length. It appears to me my size die is the issue? I do not gage sized Brass, so I cannot say for sure, but I will start.

Found this and others (LOTS) at the York 2 gun and thought I had culled them all. Then at the AGC 3 Gun I jammed a couple more into the gun.

Yes I know, I did not gage all my ammo after reloading either. Have been using the same rig (Dillon 650) for thousands of rounds before this with no issue.

I THINK that the case was too long before Lee Factory Crimp Die got it.

I use a (Worlds Finest Trimmer ?) which mounts in a drill press and uses the shoulder to reference from to get trim length. It appears to me my size die is the issue? I do not gage sized Brass, so I cannot say for sure, but I will start.

Found this and others (LOTS) at the York 2 gun and thought I had culled them all. Then at the AGC 3 Gun I jammed a couple more into the gun.

Yes I know, I did not gage all my ammo after reloading either. Have been using the same rig (Dillon 650) for thousands of rounds before this with no issue.