I'll start off saying I'm still a student of Reloading. My mere 6 yrs of reloading experience has been a pretty rewarding journey thus far. I've made great progress in a short time and honestly my hand-loads are probably more consistent than my marksmanship. I could probably stop trying to tweak out that last little bit of ballistic precision for a while....But I can't stop. After resisting turning case for a few years, I've realized there are good reasons to do so. I've started gauging the ID of each case neck and have been able to get them within 0.0005" of the my target 0.002" smaller than the projectile diameter. Yet somehow I'm still seeing odd differences in the amount of pressure it takes to seat the projectiles. This last range trip I created 20 hand loads in 6.5 Creedmoor. I carefully loaded each one and simply documented how much pressure it seemed to require to seat the projectile. I just grouped them in to three categories. I had 15 which seemed to be somewhere in the middle. I had two which appeared to require slightly less pressure to seat and three which required slightly more.

During the firing I carefully logged the projectile velocity of each round. My lab radar recorded the velocity of 16 of the 20 shots. If the 16 that I designated somewhere in the middle for seating pressure my I had data for 13 of those rounds. The MV was 2807 with an SD of 7.255fps and an ES of 23fps. For the two rounds which required less pressure, I only had data on 1 shot which was 2790. That happened to be the lowest recorded velocity of the 16 recorded shots. Interestingly for the three rounds which I had deemed required more pressure, the data recorded for two of those shots was 2815 which was the 3rd highest velocity recorded and 2821 which was the highest velocity of the string.

It's obviously not a large data set but it's interesting to see what appears to be a string correlation between bullet seating force and projectile velocity.

So where does this lead me? I think I want a hydro bullet seater. I've followed a lot of Erik Cortina's videos and seen him use the 21st Century Hydro Seater and I know a few reloaders here use them. However, it's $480 with shipping and it has a 4-8 week lead time.

I'm a bit hesitant to drop $480 on another hobby tool right now, so I started thinking about building my own. After watching a few videos and reading some of the online reviews the device looks extremely simple. It's a pressure gauge calibrated to the hydraulic cylinder size used in their press. It's probably filled with mineral oil. I convinced myself that I can make one of these for a lot less money. I'm not saying that 21st Century doesn't deserve the price they charge for their device. I'm sure it's worth it, to many serious reloaders. I'm just not ready to drop that kind of coin at this time.

Researched some parts and realized that it is going to be difficult to buy a calibrated pressure gauge set to a specific hydraulic cylinder size. However, this isnt really a show stopper. I could just do the calculations ahead of time and simply make a conversion table. This would probably be the cheapest option. However doing some math, I determined that a pressure acutator cylinder with a 1-1/8" diameter has almost exactly 1 Square Inch of Surface area. This means that any force on the cylinder shaft would almost equal the fluid pressure created within a closed system. So using a cylinder with 1-1/8" diameter means I can use any standard 0-100 PSI gauge. No conversion chart would be needed. The down side to using a 1-1/8" diameter cylinder is that I may loose some fine resolution in pressure readings.

For my initial parts list I came in at $94

Used 1-1/8" Pancake Air Cylinder - Ebay $22

100 Psi Fluid Pressure Gauge - Amazon $10

Amazon product ASIN B006H3W8IQ

Cheap Drill Press Stand - Amazon $21

Amazon product ASIN B07L3NCN9P

Various fittings, hardware and such $23

Estimated 3D printed parts $10

Mineral Oil $8

However, while searching for the pressure gauge I found really nice digital pressure gauge used for Refrigeration service for $50 (normally $86)

Amazon product ASIN B07514PS6Z

So far I'm at $134 in parts with the digital gauge.

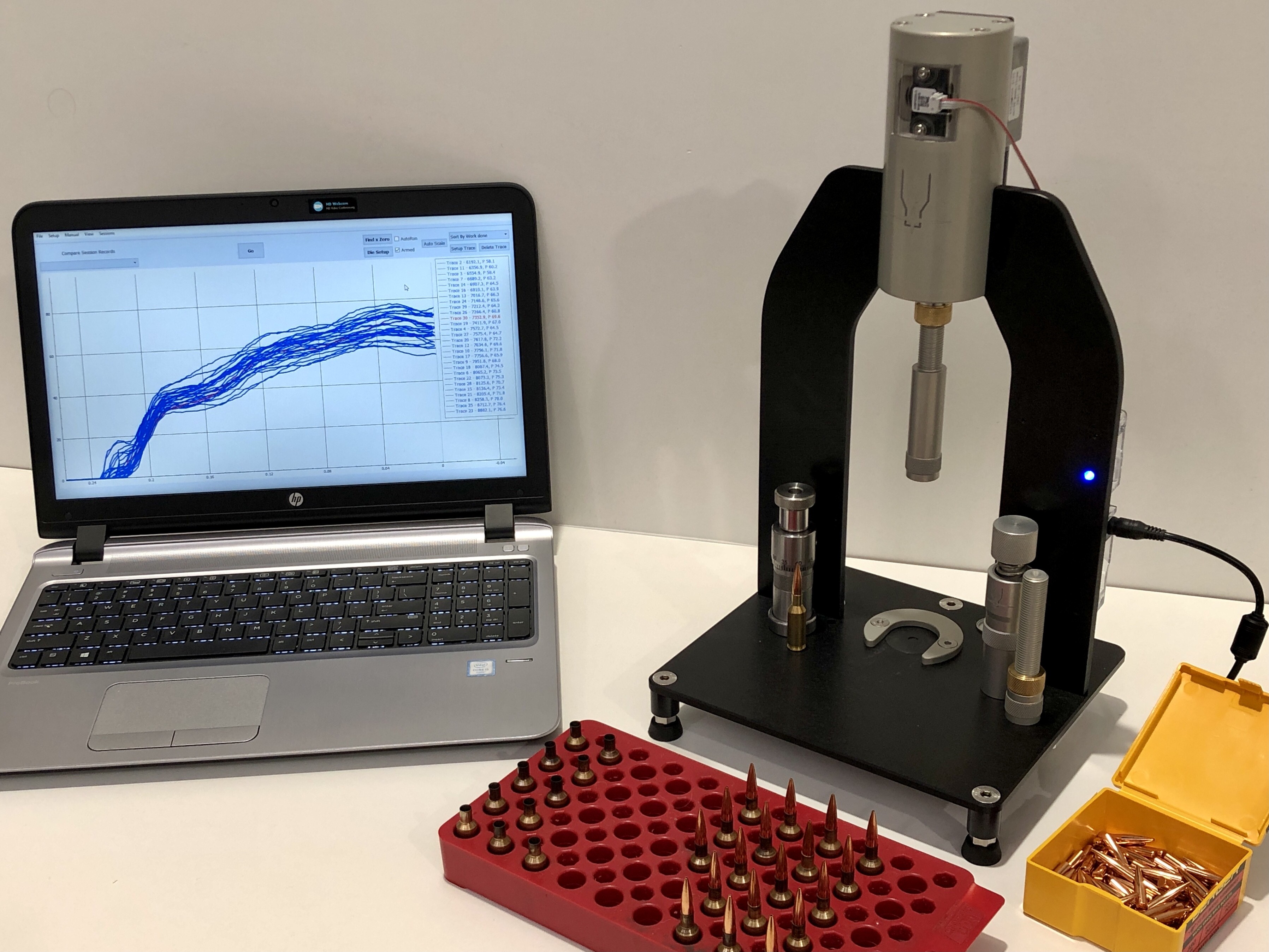

I got some of the parts today and I was excited to at least try and test out the gauge concept. I filled up the cylinder with mineral oil and attached the gauge.

I haven't had time to create any of the 3D printed adapters and mounting hardware I need to attach the gauge and cylinder assembly to the press, but I just set the gauge assembly on top of my Wilson die and pressed down on the arm to see what would happen.

So it looks like the concept is going to work pretty well. I had some mineral oil slip past the seals, so I may need to take apart the cylinder or just add some sort of small accumulator reservoir to capture any fluid that leaks past the seals. I'll also need to setup a scale the apparatus and see if I can determine how accurate the pressure gauge represents actual force pressure. I did discover once cool thing about the digital gauge. The manufacturer has an app that links to the gauge on your phone and records the pressure data real time. So you can see the reading for max pressure and there is even a graphing function. Here is a quick test just showing the pressure change as I increased and decreased the force on the press handle.

If this concept works, I may end up with an even better tool than I imagined. I'll keep you guys posted as I get the design worked out and tested over the next few weeks

During the firing I carefully logged the projectile velocity of each round. My lab radar recorded the velocity of 16 of the 20 shots. If the 16 that I designated somewhere in the middle for seating pressure my I had data for 13 of those rounds. The MV was 2807 with an SD of 7.255fps and an ES of 23fps. For the two rounds which required less pressure, I only had data on 1 shot which was 2790. That happened to be the lowest recorded velocity of the 16 recorded shots. Interestingly for the three rounds which I had deemed required more pressure, the data recorded for two of those shots was 2815 which was the 3rd highest velocity recorded and 2821 which was the highest velocity of the string.

It's obviously not a large data set but it's interesting to see what appears to be a string correlation between bullet seating force and projectile velocity.

So where does this lead me? I think I want a hydro bullet seater. I've followed a lot of Erik Cortina's videos and seen him use the 21st Century Hydro Seater and I know a few reloaders here use them. However, it's $480 with shipping and it has a 4-8 week lead time.

I'm a bit hesitant to drop $480 on another hobby tool right now, so I started thinking about building my own. After watching a few videos and reading some of the online reviews the device looks extremely simple. It's a pressure gauge calibrated to the hydraulic cylinder size used in their press. It's probably filled with mineral oil. I convinced myself that I can make one of these for a lot less money. I'm not saying that 21st Century doesn't deserve the price they charge for their device. I'm sure it's worth it, to many serious reloaders. I'm just not ready to drop that kind of coin at this time.

Researched some parts and realized that it is going to be difficult to buy a calibrated pressure gauge set to a specific hydraulic cylinder size. However, this isnt really a show stopper. I could just do the calculations ahead of time and simply make a conversion table. This would probably be the cheapest option. However doing some math, I determined that a pressure acutator cylinder with a 1-1/8" diameter has almost exactly 1 Square Inch of Surface area. This means that any force on the cylinder shaft would almost equal the fluid pressure created within a closed system. So using a cylinder with 1-1/8" diameter means I can use any standard 0-100 PSI gauge. No conversion chart would be needed. The down side to using a 1-1/8" diameter cylinder is that I may loose some fine resolution in pressure readings.

For my initial parts list I came in at $94

Used 1-1/8" Pancake Air Cylinder - Ebay $22

Fabco-Air Inc D 121 X The Pancake Line Air Cylinder for sale online | eBay

Find many great new & used options and get the best deals for Fabco-Air Inc D 121 X The Pancake Line Air Cylinder at the best online prices at eBay! Free shipping for many products!

www.ebay.com

100 Psi Fluid Pressure Gauge - Amazon $10

Amazon product ASIN B006H3W8IQ

Cheap Drill Press Stand - Amazon $21

Amazon product ASIN B07L3NCN9P

Various fittings, hardware and such $23

Estimated 3D printed parts $10

Mineral Oil $8

However, while searching for the pressure gauge I found really nice digital pressure gauge used for Refrigeration service for $50 (normally $86)

Amazon product ASIN B07514PS6Z

So far I'm at $134 in parts with the digital gauge.

I got some of the parts today and I was excited to at least try and test out the gauge concept. I filled up the cylinder with mineral oil and attached the gauge.

I haven't had time to create any of the 3D printed adapters and mounting hardware I need to attach the gauge and cylinder assembly to the press, but I just set the gauge assembly on top of my Wilson die and pressed down on the arm to see what would happen.

So it looks like the concept is going to work pretty well. I had some mineral oil slip past the seals, so I may need to take apart the cylinder or just add some sort of small accumulator reservoir to capture any fluid that leaks past the seals. I'll also need to setup a scale the apparatus and see if I can determine how accurate the pressure gauge represents actual force pressure. I did discover once cool thing about the digital gauge. The manufacturer has an app that links to the gauge on your phone and records the pressure data real time. So you can see the reading for max pressure and there is even a graphing function. Here is a quick test just showing the pressure change as I increased and decreased the force on the press handle.

If this concept works, I may end up with an even better tool than I imagined. I'll keep you guys posted as I get the design worked out and tested over the next few weeks