Hi Everybody,

When I established my pistol smithing business about four years ago, I visited several shops and ranges in Baltimore County, passed out Business cards and asked customers to please honestly post their opinions on MDShooters.com about my work quality and customer service (see link below), that I provided to them. Some did, many didn’t. Such is life. This is the only form of advertising that I do. I also depend upon word of mouth. I created this business to support my personal 1911 building hobby and to keep a little busy during retirement. However, within a few months, business grew much faster than I had anticipated. I am retired and have no interest in a full-time job. I am perfectly happy to work on about 3~4 pistols a month. This way, I can concentrate on quality and customer service (and avoid a full-time job). Like any other good business, I always want to treat customers the same way that I like to be treated, myself. I give progress updates and work carefully without regard to a time clock or having someone tell me to speed things up by forsaking quality and customer service. I simply will not do things that way. There are many fine shops in this area that have well-earned reputations. I’m also sure that most successful businesses are much more efficient than me. I am not trying to blow my horn, or put anyone down. I simply enjoy meeting shooters, listening to their needs, offering helpful suggestions and doing the work to the absolute best that I can. My biggest thrill is delivering the finished pistol back to a customer and hearing from them how much they appreciated my work! It’s a great feeling!

Until now, I have been listed in the Industry Partner section as “John Carduner, Gunsmith-1911 Specialist”. My new name is “1911 Precision, LLC”. The following narrative gives you my background, business policies, a MD Shooters link to my customer feedback, a sample price list and some pics of my custom builds.

Emails and PMs take up too much time going back and forth. I always seem to need more information, than is given. Please, call me at my business number: (410)733-4228, Monday ~ Friday, 1 PM ~ 7 PM.

Thank you!

Specializing in Actions, Reliability, Trigger Work, Customizations, Custom Builds and Repairs of Colt 1911 Pistols and Clones.

Trigger Services also available S&W Revolvers and Ruger MK I, II and III pistols. Inquire about your needs.

For Information: www.johncarduner@verizon.net

or

(410)733-4228 (Monday ~ Friday)

Hours: 1:00 PM ~ 7:00 PM

Introduction: Thank you for your interest in my gunsmithing services and products. I strive to give the utmost attention to every detail of the work I do for you, whether it be a repair, improvement, or a full custom build. I will not compromise the quality of the workmanship, parts or products used to complete the task.

Function will always be the priority in each build or repair. This doesn't mean that attention to the details in the cosmetics or form must be sacrificed. By making a commitment to only use the best parts and techniques available, I can be assured of your complete satisfaction.

A majority of my work is done by traditional hand fitting techniques that I feel will give me the most control over the finished product.

I work closely with some of the top gunsmiths and refinishing shops in the business, for tasks that require machining work or elaborate equipment such as for Welding, EDM, Hot Bluing, Hard-Chroming, Ceramic Coatings, Black Silicon Carbide (Diamond Cote) and Black Nitridization Finishes. None of this will be hidden from the customer. I stand behind all of the work provided by these excellent craftsmen. As both a Mechanical and Industrial Engineer, I have nearly 40 years’ worth of hands-on metal fabrication and metal-finishing experience. For nearly 25 of these years I worked for our nation’s Department of Defense (DoD), as an Engineer, in the Management of Major Weapon Systems. Of interest to you would be a smaller program that I worked on, the P-9 (which became the Beretta M-9 after acceptance). Additionally, I spent nearly 6 months in the late 1980s stationed at Rock Island Arsenal working closely with the National Match Armorers (I made a ton of notes). After I retired in 2007, I took a 6 month course in the building of custom 1911s.

Parts Selection: When discussing each project with the customer, special attention needs to be given to the parts selection. A quality outcome is impossible with substandard parts. I use only first quality parts from suppliers that I trust. Normally I like to obtain the parts myself, as any manufacturer can send out a substandard part. Getting the problem corrected by me directly, rather than indirectly through the customer, gives a quicker and better result. All parts that come in will be inspected and measured to insure that they meet some very strict guidelines. I reserve the right to refuse any customer provided parts that do not meet my high standards.

The above applies to everything that work on. While most modern 1911's are suitable for customization, I inspect each one that comes in, for compatibility with the project we are about to undertake.

For information regarding which firearms or parts I recommend, please contact me. If you have any questions or feedback, If you miss me on the phone, leave a voice mail with your contact info.

Customer References: The link below goes to the greatest concentration of my customer feedback on MDShooters.com. I am very proud of these write-ups:

1911 Precision, LLC offers both packaged and individual gunsmithing services. If you cannot find what you’re looking for, just e-mail or call us and we will do our best to help you. We offer specialized gunsmithing for all Colt 1911s and clones. S&W revolver services are limited to trigger/action work. All services require a minimum non-refundable deposit of at least $100.00, depending upon material and shipping costs.

All Packages and individual services shown do not include finish work. Prices shown are for test firing with customer supplied factory ammo.

1911 Basic Reliability Package* $175.00

Polish bore, hone and throat chamber

Polish barrel and receiver feed ramps to 2500 grit finish

Stone and correction-cut the bolt face

Modify, polish and tune extractor

Test fire for function; provide 25 ft test target to customer

1911 Tactical Carry Package $550.00

Polish bore, hone and throat chamber

Polish barrel and receiver feed ramps to 2500 grit finish

Stone and correction cut bolt face

Install EGW HD Extractor, modify, polish and tune

Install EGW long ejector

Install EGW oversized/flat-bottomed or radiused firing pin stop (hold extractor from clocking)

4# Trigger job with EGW skeletonized hammer, sear and disconnector

Test fire for function; provide 25 ft test target to customer

Package Extras:

Wilson Mag Well: add $95.00 (back of grips routed to eliminate unsightly gaps.)

Ambi-safety: add $35.00 plus price of safety selected (grips routed for ambi-safety if required).

1911 Individual Services

1911 Accuracy

EGW Match Bushing installed $85.00

Fit Match Barrel (labor only) $195.00

Prices on barrels upon request

Test fire for function; provide 25 ft test target to customer $35.00

1911 Replacement Sights

Generally $30.00/sight (labor) plus cost of sight(s); Add $5.00 for pinned front sight

Test fire for sight-in; provide 25 yd test target to customer $45.00

1911 Trigger Work

Carry trigger job (between 3# and 4-1/2 #) Includes EGW sear and disconnector $185.00

Competition trigger job (between 2-1/2# and 3#) Includes EGW or Koenig HD Lightened Commander Hammer, EGW sear, disconnector and sear spring $260.00

Flat-faced Match Trigger installed (solid/3-hole/med/long) $75.00

Add $25 to any trigger/ignition work being completed on Colt Series 80, Kimber Series "II" or Springfield "ILS" type pistols.

Dress all internal/mating surfaces and parts of frame

1911 Safeties

Install beavertail $125.00 labor plus part cost

Install single side safety $35.00 labor plus part cost

Install ambi safety $70.00 labor plus part cost

1911 Repairs

Replace stripped/loose grip bushing with O/S bushing (each) $12.00

1911 Extras

EDM slide lightening slots $185.00

Modify Slide Stop for Anti-Idiot Scratch Groove $20.00

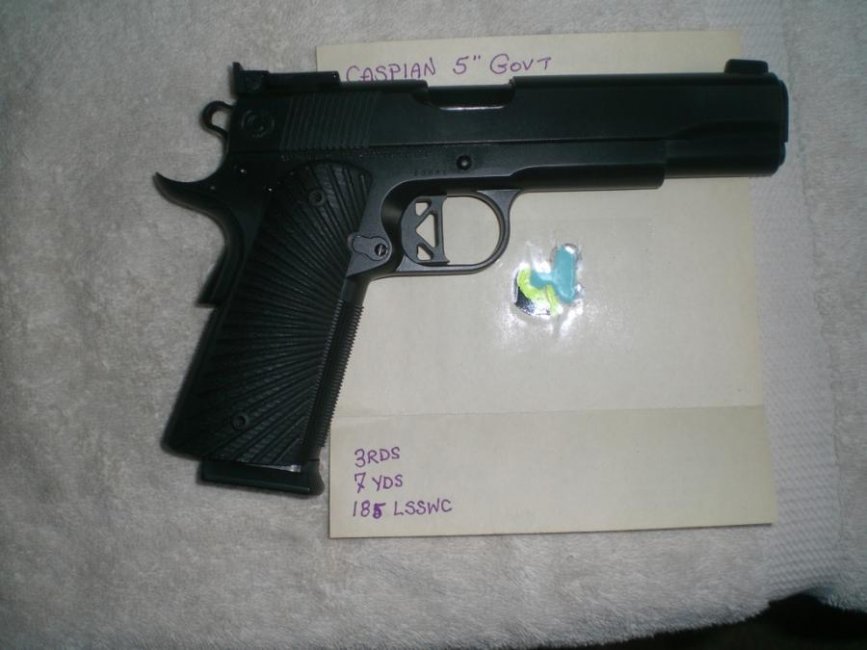

Pictures of some Custom Builds & Customizations:

When I established my pistol smithing business about four years ago, I visited several shops and ranges in Baltimore County, passed out Business cards and asked customers to please honestly post their opinions on MDShooters.com about my work quality and customer service (see link below), that I provided to them. Some did, many didn’t. Such is life. This is the only form of advertising that I do. I also depend upon word of mouth. I created this business to support my personal 1911 building hobby and to keep a little busy during retirement. However, within a few months, business grew much faster than I had anticipated. I am retired and have no interest in a full-time job. I am perfectly happy to work on about 3~4 pistols a month. This way, I can concentrate on quality and customer service (and avoid a full-time job). Like any other good business, I always want to treat customers the same way that I like to be treated, myself. I give progress updates and work carefully without regard to a time clock or having someone tell me to speed things up by forsaking quality and customer service. I simply will not do things that way. There are many fine shops in this area that have well-earned reputations. I’m also sure that most successful businesses are much more efficient than me. I am not trying to blow my horn, or put anyone down. I simply enjoy meeting shooters, listening to their needs, offering helpful suggestions and doing the work to the absolute best that I can. My biggest thrill is delivering the finished pistol back to a customer and hearing from them how much they appreciated my work! It’s a great feeling!

Until now, I have been listed in the Industry Partner section as “John Carduner, Gunsmith-1911 Specialist”. My new name is “1911 Precision, LLC”. The following narrative gives you my background, business policies, a MD Shooters link to my customer feedback, a sample price list and some pics of my custom builds.

Emails and PMs take up too much time going back and forth. I always seem to need more information, than is given. Please, call me at my business number: (410)733-4228, Monday ~ Friday, 1 PM ~ 7 PM.

Thank you!

1911 Precision, LLC

John Carduner, Owner

John Carduner, Owner

Specializing in Actions, Reliability, Trigger Work, Customizations, Custom Builds and Repairs of Colt 1911 Pistols and Clones.

Trigger Services also available S&W Revolvers and Ruger MK I, II and III pistols. Inquire about your needs.

For Information: www.johncarduner@verizon.net

or

(410)733-4228 (Monday ~ Friday)

Hours: 1:00 PM ~ 7:00 PM

Introduction: Thank you for your interest in my gunsmithing services and products. I strive to give the utmost attention to every detail of the work I do for you, whether it be a repair, improvement, or a full custom build. I will not compromise the quality of the workmanship, parts or products used to complete the task.

Function will always be the priority in each build or repair. This doesn't mean that attention to the details in the cosmetics or form must be sacrificed. By making a commitment to only use the best parts and techniques available, I can be assured of your complete satisfaction.

A majority of my work is done by traditional hand fitting techniques that I feel will give me the most control over the finished product.

I work closely with some of the top gunsmiths and refinishing shops in the business, for tasks that require machining work or elaborate equipment such as for Welding, EDM, Hot Bluing, Hard-Chroming, Ceramic Coatings, Black Silicon Carbide (Diamond Cote) and Black Nitridization Finishes. None of this will be hidden from the customer. I stand behind all of the work provided by these excellent craftsmen. As both a Mechanical and Industrial Engineer, I have nearly 40 years’ worth of hands-on metal fabrication and metal-finishing experience. For nearly 25 of these years I worked for our nation’s Department of Defense (DoD), as an Engineer, in the Management of Major Weapon Systems. Of interest to you would be a smaller program that I worked on, the P-9 (which became the Beretta M-9 after acceptance). Additionally, I spent nearly 6 months in the late 1980s stationed at Rock Island Arsenal working closely with the National Match Armorers (I made a ton of notes). After I retired in 2007, I took a 6 month course in the building of custom 1911s.

Parts Selection: When discussing each project with the customer, special attention needs to be given to the parts selection. A quality outcome is impossible with substandard parts. I use only first quality parts from suppliers that I trust. Normally I like to obtain the parts myself, as any manufacturer can send out a substandard part. Getting the problem corrected by me directly, rather than indirectly through the customer, gives a quicker and better result. All parts that come in will be inspected and measured to insure that they meet some very strict guidelines. I reserve the right to refuse any customer provided parts that do not meet my high standards.

The above applies to everything that work on. While most modern 1911's are suitable for customization, I inspect each one that comes in, for compatibility with the project we are about to undertake.

For information regarding which firearms or parts I recommend, please contact me. If you have any questions or feedback, If you miss me on the phone, leave a voice mail with your contact info.

Customer References: The link below goes to the greatest concentration of my customer feedback on MDShooters.com. I am very proud of these write-ups:

1911 Precision, LLC offers both packaged and individual gunsmithing services. If you cannot find what you’re looking for, just e-mail or call us and we will do our best to help you. We offer specialized gunsmithing for all Colt 1911s and clones. S&W revolver services are limited to trigger/action work. All services require a minimum non-refundable deposit of at least $100.00, depending upon material and shipping costs.

All Packages and individual services shown do not include finish work. Prices shown are for test firing with customer supplied factory ammo.

1911 Basic Reliability Package* $175.00

Polish bore, hone and throat chamber

Polish barrel and receiver feed ramps to 2500 grit finish

Stone and correction-cut the bolt face

Modify, polish and tune extractor

Test fire for function; provide 25 ft test target to customer

1911 Tactical Carry Package $550.00

Polish bore, hone and throat chamber

Polish barrel and receiver feed ramps to 2500 grit finish

Stone and correction cut bolt face

Install EGW HD Extractor, modify, polish and tune

Install EGW long ejector

Install EGW oversized/flat-bottomed or radiused firing pin stop (hold extractor from clocking)

4# Trigger job with EGW skeletonized hammer, sear and disconnector

Test fire for function; provide 25 ft test target to customer

Package Extras:

Wilson Mag Well: add $95.00 (back of grips routed to eliminate unsightly gaps.)

Ambi-safety: add $35.00 plus price of safety selected (grips routed for ambi-safety if required).

1911 Individual Services

1911 Accuracy

EGW Match Bushing installed $85.00

Fit Match Barrel (labor only) $195.00

Prices on barrels upon request

Test fire for function; provide 25 ft test target to customer $35.00

1911 Replacement Sights

Generally $30.00/sight (labor) plus cost of sight(s); Add $5.00 for pinned front sight

Test fire for sight-in; provide 25 yd test target to customer $45.00

1911 Trigger Work

Carry trigger job (between 3# and 4-1/2 #) Includes EGW sear and disconnector $185.00

Competition trigger job (between 2-1/2# and 3#) Includes EGW or Koenig HD Lightened Commander Hammer, EGW sear, disconnector and sear spring $260.00

Flat-faced Match Trigger installed (solid/3-hole/med/long) $75.00

Add $25 to any trigger/ignition work being completed on Colt Series 80, Kimber Series "II" or Springfield "ILS" type pistols.

Dress all internal/mating surfaces and parts of frame

1911 Safeties

Install beavertail $125.00 labor plus part cost

Install single side safety $35.00 labor plus part cost

Install ambi safety $70.00 labor plus part cost

1911 Repairs

Replace stripped/loose grip bushing with O/S bushing (each) $12.00

1911 Extras

EDM slide lightening slots $185.00

Modify Slide Stop for Anti-Idiot Scratch Groove $20.00

Pictures of some Custom Builds & Customizations:

Attachments

-

6inch.jpg50 KB · Views: 976

6inch.jpg50 KB · Views: 976 -

CIMG0789.jpg95.2 KB · Views: 967

CIMG0789.jpg95.2 KB · Views: 967 -

CIMG1028.jpg74.2 KB · Views: 969

CIMG1028.jpg74.2 KB · Views: 969 -

CIMG1031.jpg72.2 KB · Views: 967

CIMG1031.jpg72.2 KB · Views: 967 -

CIMG1036.jpg66.5 KB · Views: 975

CIMG1036.jpg66.5 KB · Views: 975 -

CIMG1041.jpg68.5 KB · Views: 966

CIMG1041.jpg68.5 KB · Views: 966 -

DSC_0957.jpg78.7 KB · Views: 964

DSC_0957.jpg78.7 KB · Views: 964 -

CIMG1052.jpg58.5 KB · Views: 968

CIMG1052.jpg58.5 KB · Views: 968 -

PATRIOT 85.jpg93.7 KB · Views: 957

PATRIOT 85.jpg93.7 KB · Views: 957 -

CIMG1046.jpg69.8 KB · Views: 975

CIMG1046.jpg69.8 KB · Views: 975

Last edited: