toolness1

Ultimate Member

Hello, I have been casting and powder coating bullets for just a couple weeks now. I have had a lot of success, already finding accurate loads for cast/powder coated 9mm, 9x18, 8x56R, and 8mm Mauser.

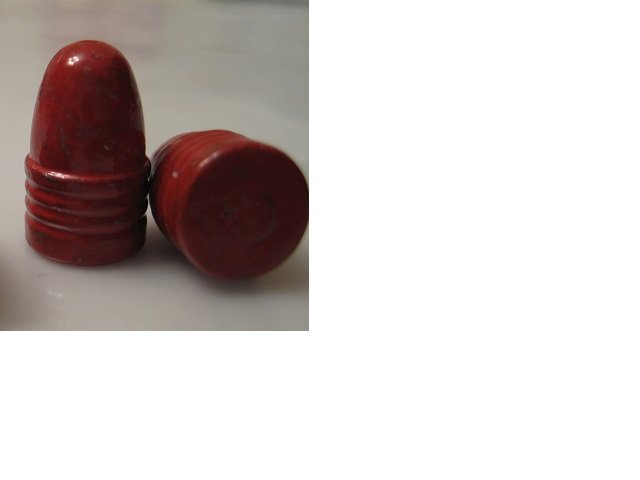

The biggest issue I have had is this: some of my bullets come out of the oven after baking and look like they melted and sag down into the screen I bake them on. The strange thing is, I usually only bake up to 350-375 DegF or so, for about 20 min. My screen is a "tray" I made out of 1/4'' mechanic's cloth.

On this last batch of 9mm, I had 15 that came out like the ones in the picture, flattened/melted. The other 68 that were on the same screen, in the same batch, in the same oven, came out perfect.

How come some, seemingly randomly, are melting like this?

I can live with this issue, as most come out fine and I'll just melt the bad ones down and re-cast, but it's bugging me because I can't figure out why it's happening.

I do have a thermometer in my toaster oven I use. I monitor the temp through the 20 min bake time to see if it's spiking, and it doesn't seem to be. The positioning on the screen/in the oven doesn't seem to matter as far as which ones melt.

I'm using red Harbor Freight powder coat, and dry tumbling them in a tupperware with copper plated BB's, which I place in my Lyman tumbler for about 20 min.

Thanks for any help/comments!

The biggest issue I have had is this: some of my bullets come out of the oven after baking and look like they melted and sag down into the screen I bake them on. The strange thing is, I usually only bake up to 350-375 DegF or so, for about 20 min. My screen is a "tray" I made out of 1/4'' mechanic's cloth.

On this last batch of 9mm, I had 15 that came out like the ones in the picture, flattened/melted. The other 68 that were on the same screen, in the same batch, in the same oven, came out perfect.

How come some, seemingly randomly, are melting like this?

I can live with this issue, as most come out fine and I'll just melt the bad ones down and re-cast, but it's bugging me because I can't figure out why it's happening.

I do have a thermometer in my toaster oven I use. I monitor the temp through the 20 min bake time to see if it's spiking, and it doesn't seem to be. The positioning on the screen/in the oven doesn't seem to matter as far as which ones melt.

I'm using red Harbor Freight powder coat, and dry tumbling them in a tupperware with copper plated BB's, which I place in my Lyman tumbler for about 20 min.

Thanks for any help/comments!